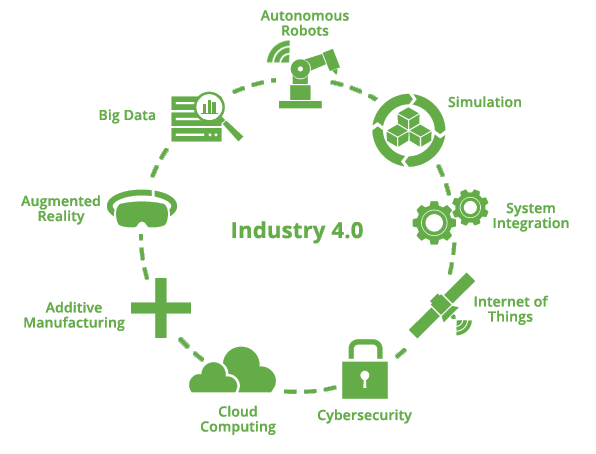

Industry 4.0 (aka the Fourth Industrial Revolution) has been sparked by global technological trends which enable the convergence of physical-digital systems, in turn causing massive transformations in the way manufacturers create, service and operate their new smart, connected products.

New technological trends which have enabled this advent of automation and data exchange in manufacturing technologies include:

- Industrial Internet of Things (IIoT),

- Cloud computing,

- Augmented reality (AR), and

- Digital twin.

LEAP Australia is proud to partner with PTC and ANSYS who are at the forefront of this new, connected revolution; bringing together traditional manufacturing and design tools such as computer modelling, data management and simulation and connecting them through the Internet of Things to enable true end-to-end product lifecycle management.

Industrial Internet of Things

The Internet of Things (IoT) enables insights into product performance, usage and customer experience that were not previously possible. Real time access to usage data provides companies with feedback that improves their products at every level – from initial design and manufacture to delivery and service to end of life management and iterative design improvements. The ability to fully understand not only the performance but also how a product is consumed by the end user facilitates better quality in-life service and transforms a simple ‘thing’ that leaves the factory into a service and ongoing relationship with customers over the lifecycle of the product and beyond.

Augmented Reality

While Augmented Reality (AR) was popularised through the recent Pokemon Go phenomenon, the applications for industry are more far reaching. Computer models and simulation results can be visualised through AR during the design stage, allowing for virtual prototypes to be examined in the physical world. IoT data can be visualised on a working product providing insight into internal conditions without the need for monitors, gauges or dials and entire factories can be overlayed with data to provide real time information about performance, materials and stock levels and much more. Sales and marketing teams can even use AR to demonstrate products to potential buyers without physical stock and examine various configurations or variations of a product on the fly.

Thyssenkrupp utilises AR with the HoloLens to empower their service technicians to perform their jobs more safely and efficiently. Check it out in the video below.

For more information on Industry 4.0 check out the Harvard Business Review article, How Smart Connected Products are Transforming Companies.

Digital Twin

When a product is IoT enabled the data collected from its performance in the real world can be tracked in real time and fed back into digital modelling tools to create a digital twin. The digital twin is then used to monitor performance and operating conditions to identify problems as or even before they arise and investigate and implement solutions on the fly. By displaying live data from the operational product, the digital twin provides unprecedented insight into what is happening ‘under the hood’, visualising any measurable data sources in real time. Check out the video below demonstrating how Flowserve have implemented the digital twin to better understand and improve their pump designs.

For more examples of the Digital Twin, download the ANSYS Advantage Magazine – Spotlight on the Digital Twin

Why choose LEAP?

Our 20-year history of helping companies build better products faster and more efficiently places us in a unique position within the local industry. LEAP Australia partners, PTC and ANSYS, are at the forefront of Industry 4.0 technologies globally. Using the PTC Thingworx IoT platform and associated technologies, we are facilitating the digital transformation of traditional design and manufacturing processes and helping our customers move into the age of Industry 4.0.