The Best Products Are Designed Using The Best Engineering Software

The Ellton Conveyors division of the Ellton Group provides an integrated service in materials handling design, supply, construction, commissioning, training and operational support.

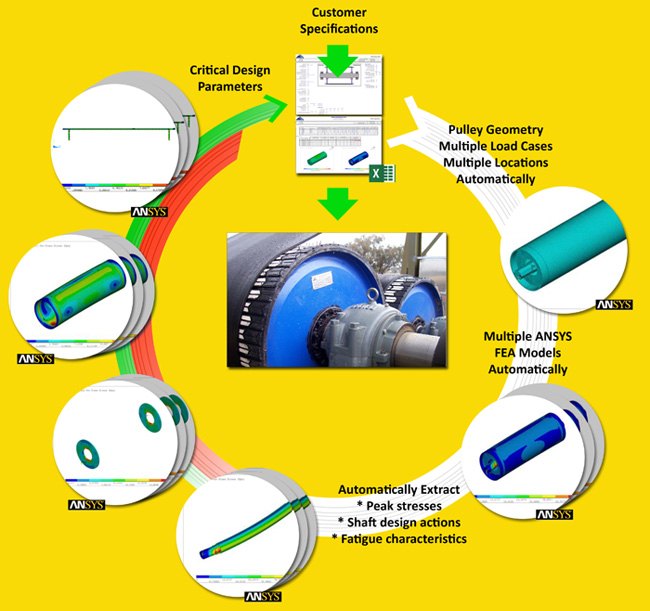

Mechanical Engineers at Ellton design customised conveyor pulleys to meet their customer’s exact requirements. Ellton has developed a pulley design process leveraging the parametric capabilities of the ANSYS design suite to enable the evaluation of pulley designs across a range of locations and load cases simultaneously. This enables easy rationalisation of pulley designs across a conveyor or system of conveyors.

“We have created a workflow which allows us to rapidly drive the entire pulley design process from Microsoft Excel, whilst utilising the proven capabilities provided by ANSYS software in every design iteration.” Peter Weatherhead, Lead Engineer – Materials Handling

The process automatically creates multiple finite element models of the pulley from user input and returns critical design parameters to an Excel spreadsheet for evaluation. The results from ANSYS FEA software give them the information they need quickly and provides greater insight than traditional pulley design techniques.

The Ellton pulley design process automatically evaluates a design for numerous locations and load cases using ANSYS

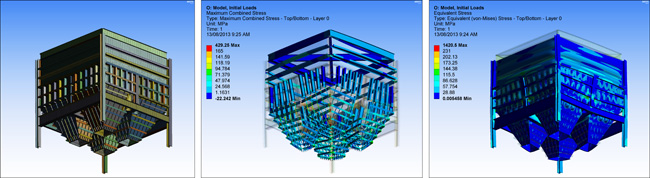

Ellton also work on more complex Engineering problems and ANSYS gives them the flexibility they need to run all types of structural simulations.

The bin shown below is a large FE model utilising a combination of shell and beam elements with complex loading.

ANSYS is fast and robust so models such as this can be set up and solved quickly and accurately. This means the Engineers at Ellton can do more simulations, look at more alternatives and in general be confident they have produced the best design to meet their customer’s requirements.

“We purchased ANSYS software from LEAP Australia, and have found their technical support to be second to none.” Peter Weatherhead, Lead Engineer – Materials Handling

Ellton Conveyors: deliver innovative, reliable and safe technical or product solutions to the mining and bulk handling markets using in house resources coupled with specialist international engineering partners. www.conveying.com.au