XPLM Integration Solutions – the efficient connection between ECAD and PTC Windchill

Integrate your ECAD design development process – with the centralised management of native design data and the generation of BOMs, fabrication and assembly data.

THE CHALLENGES

The need for consistent information flows and processes, and to be able to launch innovative and high-quality products, are just some of the challenges companies face when trying to manage the efficient collaboration of design teams across various locations.

Coupled with the new challenges created for businesses by digital transformation and the prevalence of Industry 4.0 and IoT, companies are increasingly searching for a solution to facilitate cross-disciplinary cooperation in their production of complex products.

THE SOLUTION

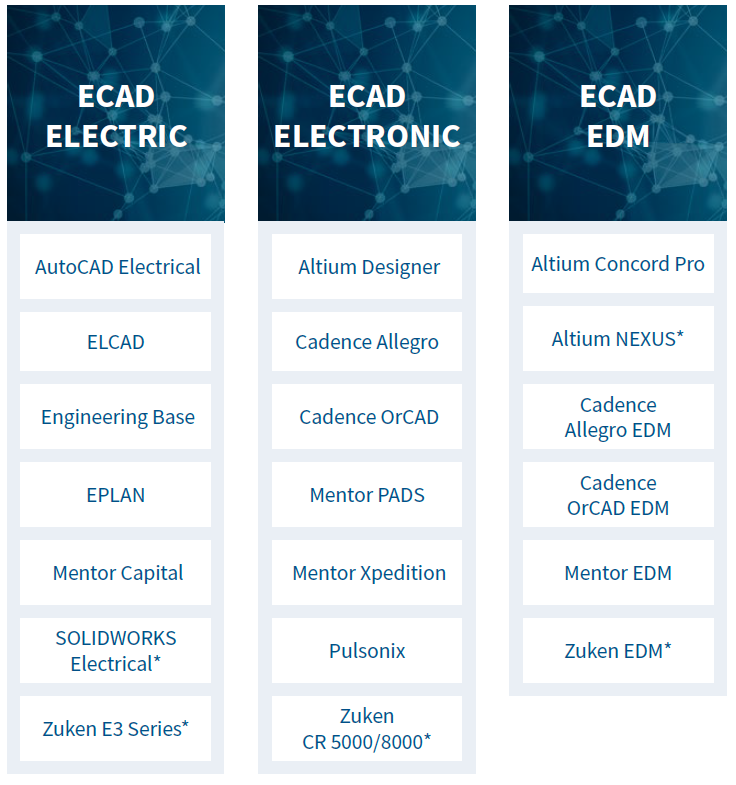

XPLM offers solutions for PTC Windchill that enable an integrated approach to connect your ECAD design workflow to the complete product design ecosystem. This allows cross-discipline collaboration across design teams and combines mechanical, electrical, embedded software and electronic design data on a single platform.

XPLM integration tools allows for ECAD design data to be managed more consistently, improving efficiency, agility and process reliability and providing engineers a complete view of their product data. Designers can now access, publish and synchronize information without leaving their familiar ECAD environment. The integrated approach moreover enhances the ability to hit release dates, cost targets, product quality and feature set goals.

MAIN FEATURES

XPLM’s integration solutions for PTC Windchill manages native ECAD design data and the generated manufacturing data inside PLM by using standardized functionalities:

- Starting new projects with default project templates

- Complete release of projects including automatic creation of fabrication and documentation outputs into PLM

- Automatic population of parameters in drawing frames

- Generation of Bill of Materials including design variants

- Comparison of Bill of Materials during save of the design project

- Check-in and check-out capabilities

- Bidirectional on-demand or batch mode synchronization of library content

- Extensive search capabilities

- Easy linking of data to other PLM objects

- Solid audit trail via status log

KEY BENEFITS

- Save time and eliminate errors through consistency in automated data exchange processes and data model

- Avoid redundancy by using a single integrated platform

- Achieve holistic traceability of your product development processes by incorporating ECAD design data into the business processes

- Make design information accessible to users outside the ECAD world

- Enhance collaboration through simplified multi-site data exchange

- Prevent duplicate data entry in ECAD library & PLM

- Adapt the integration functionalities to your operational processes

- Shorten your search times to access design data more quickly

- Avoid manual processes

The video below is an excerpt from our recent webinar, Managing the Complete MCAD & ECAD BOM in Windchill PLM. Watch to see how XPLM’s integration tools work or see the full presentation here.