Customer Testimonials

For 25+ years, LEAP has assisted thousands of companies from diverse industries to implement technology solutions to digitise their product development processes.

Here we have collated customer testimonials and case studies which highlight some of the amazing work our customers across Australia and New Zealand have done utilising our solutions.

Malcolm Falconer, Senior Mechanical Design Engineer at Tait Communications, explains how Tait uses PTC Creo to design, collaborate and visualise their product designs and enable rapid virtual prototyping; and PTC Windchill PLM to secure Tait’s CAD data to enhance collaboration, reduce errors and for revision control during the design and development process.

Hear from Glenn Jewell, Head of Operations at Kite Magnetics who explains how Kite Magnetics use Creo for 3D CAD product design and Ansys for low-frequency electromagnetic motor simulations, and learn more about how Kite Magnetics’ Aeroperm material helps make electric motors 25% smaller, lighter, and more efficient!

Committed to the highest quality learning standards, Monash University is reimagining what learning looks like. Leveraging PTC solutions, they are preparing engineering students for the workforce with a pilot program designed to engage students with the advanced technologies widely used in the real world. Read the full case study to learn how they’re finding success with a new way of learning.

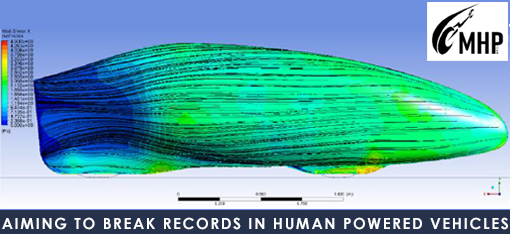

Monash Human Power (MHP) aims to design a recumbent bike to ultimately break the world speed record for human powered vehicles As a student team, MHP is limited in budget and resources so uses Ansys simulations early in their design cycle for testing new ideas in both aerodynamics and chassis design.

Over the past quarter-century, America’s Cup racing yachts have undergone sweeping shifts in their form and function to comply with evolving design rules. During that same period, Emirates Team New Zealand has pioneered and extended its use of Ansys simulation software in its design process to become a premier racing syndicate.

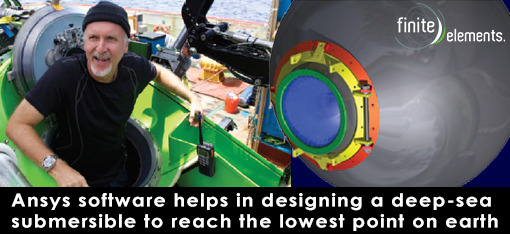

In 2012, Canadian film director and experienced submariner James Cameron solo piloted the DEEPSEA CHALLENGER to the lowest-known point on Earth — Challenger Deep, 11,000 meters beneath the sea. The crucial structural elements of the vessel were engineered and optimised in Ansys by Finite Elements, an engineering design consulting company based in Tasmania.

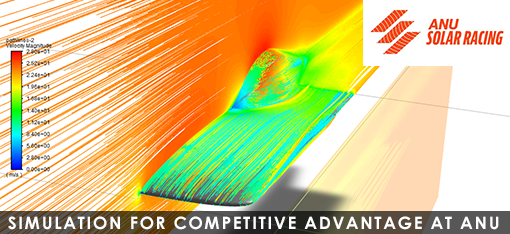

To be competitive in the Bridgestone World Solar Challenge, the team at ANU Solar Racing uses simulation to rapidly consider a variety of virtual chassis designs before committing to a design for the final build. ASR engineers carefully consider trade offs between a need for reliability against the need for aerodynamic efficiency and weight minimisation to remain competitive.

For over 15 years, LEAP has supported Monash Motorsport (MMS) and their use of Ansys simulation tools to improve and optimise the design of their vehicles. Here we have compiled some of the articles we have created in collaboration with MMS – read on to learn how Ansys has helped MMS become the premier Formula SAE team in Australia.

Want to learn more about LEAP’s solutions?

Complete the form and our team will contact you to discuss your needs.

EMVision used Ansys Mechanical to simulate the non-linear material behaviour of the viscoelastic rubber membrane in their portable brain scanner, delivering comfort, safety and performance across a variety of head sizes and shapes.