In September the University of Auckland was abuzz with a NZ-first – a hackathon focused on the emerging industrial applications for technologies such as Internet of Things (IoT) and Augmented Reality (AR). The Hackathon was held in collaboration between Callaghan Innovation, LEAP Australia, and the University of Auckland’s Faculty of Engineering and gave six multidisciplinary student teams the chance to develop and present IoT and AR-based solutions to a series of real-world problems submitted by local industry.

The main aims driving the university to hold this Hackathon were to:

- demystify IoT and AR for both students and industry

- allow students to use available commercial off-the-shelf IoT and AR software to tackle real-world problems in a short timeframe

- deliver implementable solutions which also closely consider the business value to industry

For the problem sponsors from NZ industry, the motivating factors were:

- getting a solution rapidly developed for a real business problem on a low budget

- eliminating development risk while receiving a high-fidelity technology demonstration

- rapdily building a business case for emerging technologies based on facts and a real ready-to-go, scalable solution

So what were the outcomes? You can watch a selection of highlights and feedback from key participants in this video:

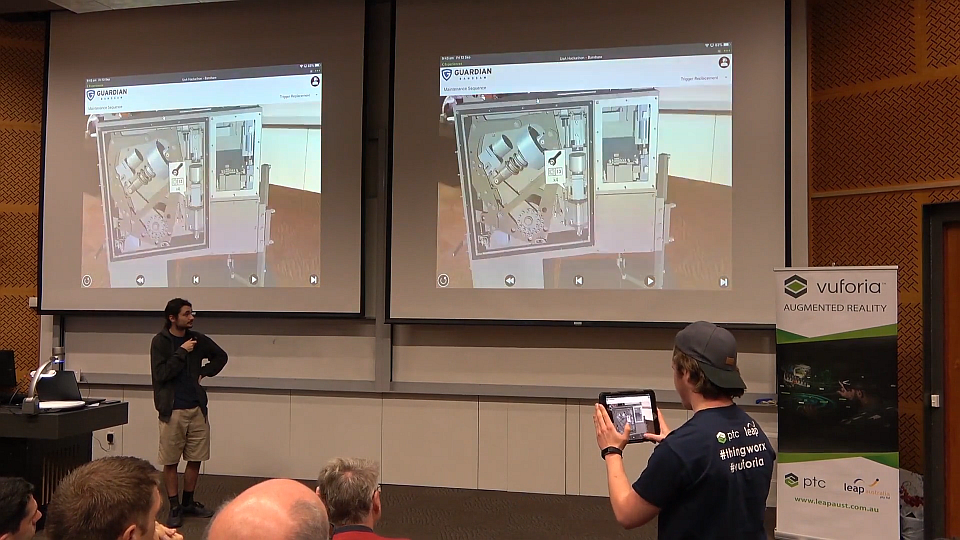

Six student teams participated in the Hackathon – starting with a two-day training session (with mentoring from LEAP in the ThingWorx IoT and Vuforia Studio AR software platforms), followed by two days of the hackathon itself, and a final presentation day where each team delivered their solution to an audience including a panel of judges chosen from local industry bodies and academia. Students were drawn from diverse backgrounds and included undergraduate to PhD levels across the University of Auckland’s Engineering, Science, and Business faculties.

The best thing about this was that there’s no coding barrier. The modules LEAP provided for the software were really informative so we didn’t need any prior IoT knowledge. The experts also helped out whenever we needed them.

Electrical and Electronic Engineering masters student Nilesh Patel Tweet

Industry mentors from LEAP and Callaghan Innovation provided guidance for the student teams, with technical experts particularly in demand on Day 1 as students began applying their work to the Microsoft Hololens using PTC software such as Creo, Creo Illustrate, ThingWorx and Vuforia Studio. Representatives from the industry problem sponsors also visited during the Hack days to observe and provide feedback to the competing teams. Feedback from other students was that the hackathon was a valuable experience as engineering students typically do not have the opportunity to work together with students from other disciplines outside their normal classes.

See more feedback and highlights from Uni of Auckland students and staff in this video:

The Faculty of Engineering at the University of Auckland is positioned as a leading training ground for skilled engineers in New Zealand. Phil Anderson from Callaghan Innovation sees the Faculty of Engineering’s extensive research partnerships with local companies as a critical advantage, which is visible in the research work performed by academic staff involved in coordinating the Hackathon: Dr Vicente Gonzalez, leader of the Advanced Computing and Virtual Technologies in Construction research group, Professor Xun Xu, head of the Laboratory for Industry 4.0 Smart Manufacturing Systems, and Dr David Wynn, leader of the Design and Development research group.

Professor Xu says, “we can’t also forget the added experience of business innovation for our students. The problems aren’t purely technological; some require a change in business models or redefining value propositions.”

The problems submitted by industry sponsors — Assa Abloy, NZ Safety Blackwoods, GHD Digital, kanDO / Guardian Bandsaw, Hynds Pipe Systems, and Holmes Solutions — were of a broad variety, from the logistics of stock tracing and recognition, to building brand awareness and customer relationships. Dr Gonzalez considers that the range of submissions, which came from civil to mechanical companies, reveals that these technologies are becoming normalised, and knowing how to apply them is more relevant than ever.

The students were notably able to visit or contact the sponsor companies directly to investigate the challenges. Akshat’s team excursion to Assa Abloy’s Albany factory was immensely helpful.

It was hard to imagine what simply providing an IoT or image recognition solution would look like. Meeting their staff and seeing their environment was immediately useful. We got a sense of who they are, which was very organised and on point, with very loyal employees. We could get on the same page with expectations, and come up with what’s actually a cost-friendly solution for their company.

Akshat Chabra, Master in Engineering Studies student in Electrical and Electronics Engineering Tweet

David Wynne praised the enthusiasm and dedication of the participating students, saying “the students are dedicating their time during study break to be here, which is great. It’s a lot of commitment”. Student Thomas Lovelock adds, “there’s something about putting myself outside my comfort zone, and seeing that I am achieving more than I thought I’m able to. When we got told on Monday what our problems were, I considered pulling out of this! But then on Thursday, I could see an end in sight and I was glad I stuck it out, because it was just really cool.”

In this deeper-dive video below, hear feedback from Callaghan Innovation, John McDermott from the NZ IoT Alliance (who acted as a judge during the final team presentations) and Nivin Brown from kanDo Innovation who sponsored one of the industry problems:

Andrew Gill, Industrial Associate from the University of Cambridge Institute for Manufacturing served as one of five judges at the event. He remarked that “I was very impressed with the commitment and enthusiasm of the teams. They covered a lot of ground in a short period if time and I would expect the sponsoring companies to be very happy with the insights and recommendations produced.”

Professor Xu concludes that “the decision to support this event was an easy one to make. It’s a win-win situation for all three parties involved: the software providers propelling IoT/AR technologies into New Zealand industry, local businesses trialling out these solutions for problems they are facing, and our students gaining hands-on technical exposure in real-life situations. It is a no-brainer.”

For more information on future IoT and AR Hackathons, contact LEAP Australia here: leapaust.com.au/hackathon/