Acoustics Simulation

All product designers and engineers must consider the noise a product will generate as an increasingly important factor. This applies whether the product is designed to create noise, such as a hearing device or speaker, is intended to dampen noise such as a muffler, or has potential to create noise as an unexpected by-product through turbulence, friction or structural vibration.

Best-in-class companies are now bringing forward their assessment of a product’s acoustic performance, rather than run the risk of facing a costly build-and-test scenario later in the design stage. By utilising Ansys acoustics simulation techniques to analyse designs early in the design process with a virtual prototype, engineers can significantly reduce production lead times and avoid costly re-engineering processes.

Ansys VRXPERIENCE SOUND

With Ansys VRXPERIENCE Sound, you can listen to, analyze and design sound sources. Create immersive 3D soundscapes to enhance your product or your simulations based on recordings, CAE simulation outputs or your virtual reality (VR) environment.Acoustics analysis can be performed in several ways, either as a pure acoustic problem, or as a coupled vibro acoustic problem.

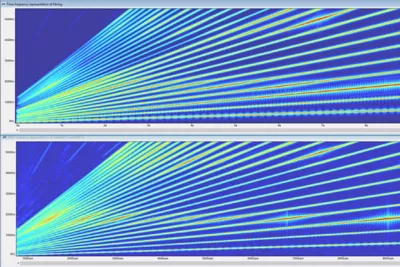

Sound Analysis and Sound Quality

VRXPERIENCE Sound offers a powerful suite of analysis tools focusing on sound perception. An intuitive graphic display of sounds and a one-click magnification control feature help create the perfect sound signature for your product. With the software, you can also set up psychoacoustic tests based on a listener panel, and obtain statistics about the real perception of your sounds. As a result, you can achieve and deliver the best sound.

You can also evaluate and improve the way a sound is perceived, by using tools based on time-frequency representations.

3D-Sound Playback Systems

VRXPERIENCE Sound uses state-of-the-art 3D recording and playback techniques that create high-precision reproductions of 3D sounds and original timbres in a predefined space. You will discover how sound perception maximizes immersion in a specific real or virtual place.

Interactive Audio Simulators

VRXPERIENCE Sound systems are specially designed to equip your simulators and VR platforms. Available for cars, aircraft and trains, they create realistic, interactive 3D soundscapes using real-time audio sound generation, which can be integrated with your simulators and platforms.

Engine Sound Design

VRXPERIENCE Sound provides the Active Sound Design (ASD) comprehensive solution for engine sound enhancement (ESE) for electric vehicles (EVs) and internal combustion engine (ICE) cars.

Listen to Mechanical and Fluids Simulations

With VRXPERIENCE Sound, you can listen to Ansys Mechanical, Ansys Fluent, Ansys LS-DYNA and Ansys Motion simulations, modify sounds to evaluate effects of level changes on components, and run a study on sound quality. To learn more about VREXPERIENCE Sound read our recent blog post here.

Capabilities

Discover multiple aspects of your products’ acoustic properties through in-depth testing, simulating and analyzing, all with the goal of improving a final design early in the development process.

Listen to and Analyse Sound Quality

Based on real test measurement or acoustic CAE simulation, listen and separate the sound sources, to then analyse the sound and improve the sound quality.

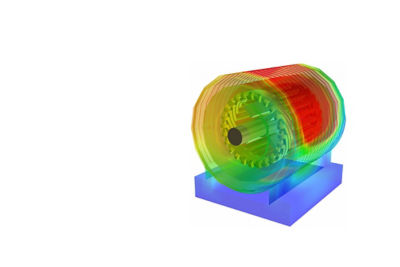

Optimise Engine Sound for E-Motor

E-motor optimisation means you can simulate the noise radiated by the e-motor and optimise designs according to acoustic KPI or sound quality criteria.

Listen to Mechanical and Fluids Simulations

Through vibro-acoustic and CFD simulations, you can listen to the sound of your virtual prototype and optimise the acoustic performance and sound quality at the beginning stages of the design process.

Evaluate Sound Perception with Jury Testing

Along with qualitative testing, acoustic design includes real-world perception—something Ansys evaluates with jury testing tool, with several psychoacoustic methods including statistical analysis.

From Component-level Acoustic Simulation to System-level Sound Rendering

Combining simulation results, lab measurements recordings and acoustic transfer path, you can listen to your product and each of the components of your system in a fully realistic environment, like a driving or flight simulator.

Want to learn more about Ansys simulation solutions?

Complete the form and one of the experts from our Ansys team will contact you to discuss your needs.