Environmental Sustainability is one of the key macro trends that are forcing changes to manufacturing businesses worldwide, with engineers and managers obliged to re-evaluate their product design and manufacturing processes to meet increasing regulatory requirements as well as internal sustainability goals.

Did you know that 80% of the environmental impact of your product is already determined by early decisions regarding part design, materials and manufacturing process? Our recent webinar presented by experts from LEAP and MAIT described how a systematic approach to part management with Windchill PLM and Geometric Similarity Search using ModelSearch can help you achieve both financial and key sustainability goals, such as:

• Reductions in unnecessary part variety (avoiding needless use of identical or “very similar” re-usable parts)

• Improved energy efficiency and waste reduction from part standardisation

• Optimised procurement and supply chain decisions

• Simplified maintenance and repair processes

In this article we have summarised this webinar and included key sections of the recording. To start, Paul O’Shaughnessy, PTC Business Manager at LEAP provides an introduction to both LEAP and MAIT and explains their partnership and ModelSearch.

Next, Allan Thompson, PTC Technical Manager at LEAP explains the pivotal role of PLM in delivering a successful environmental sustainability initiative across your organisation by improving transparency and traceability across the entire product lifecycle and supply chain.

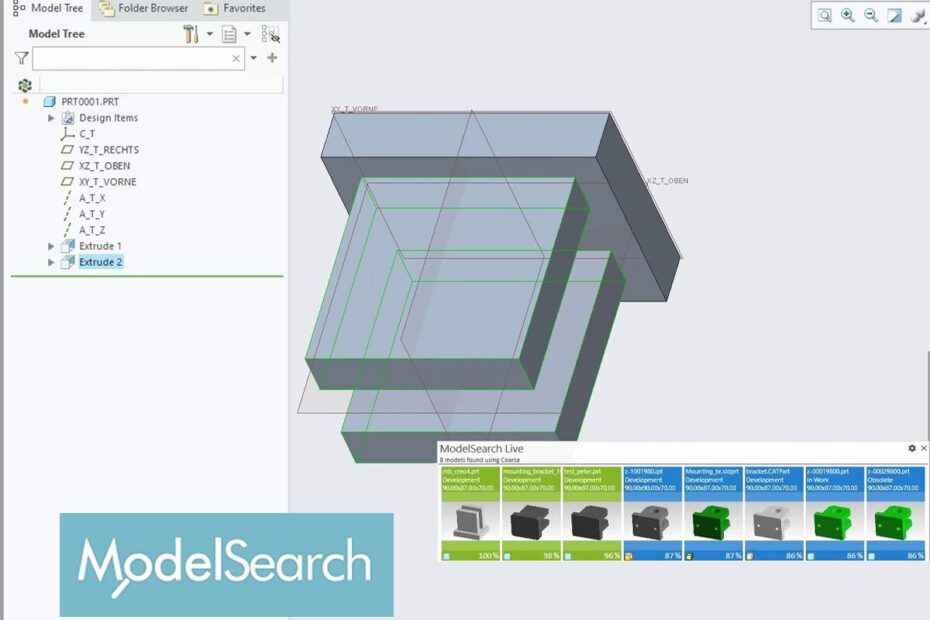

Next Philipp Hinterdorfer, Product Manager, ModelSearch at MAIT provides an overview of ModelSearch’s capabilities and features. Philipp then discusses how improved Part Control inside PLM and use of ModelSearch’s unique Geometric Similarity searches can help design engineers and production/inventory managers to identify and reduce the number of very similar, identical parts in a product, in turn significantly reducing the time and resources required to create new parts (and removes unnecessary costs associated with design, tooling, production, shipping and warehousing).

Finally, Philipp provides a deep-dive, live demonstration of ModelSearch. The demonstration provides examples of the various features ModelSearch can search for and how similarity weighting can be utilised to identify non-identical parts that may still be useful for your design.

Watch the video below for a complete demonstration of ModelSearch in action!

We trust that you found this article informative. If you have any questions or would like to learn more about how ModelSearch can improve the efficiency of your own design processes, please dont hesitate to contact us to speak with an expert at LEAP.