Guest Blog by Dr. Jacky Zhou, School of Chemical & Biomolecular Engineering, University of Sydney

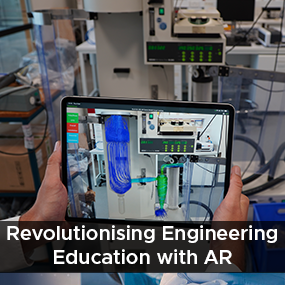

In the light of technological advancements, the boundaries of traditional learning methods are being expanded. Virtual technologies like augmented reality (AR) emerge as a new trend in the evolution of teaching and training methods in fields with a high degree of visualisation and interaction, including chemical engineering. This post aims to bring you the latest applications of AR technologies for chemical engineering at a world-leading higher education institution.

The Paradigm Shift: AR in Chemical Engineering

The Intersection of AR and Chemical Engineering Education

Chemical engineering, combining the law of physics and chemical reactions, often presents a steep learning curve. Traditional tools have always come short of delivering the complex phenomena within the three-dimensional chemical machinery. The integration of Augmented Reality, a technology that overlays digital information into the real world, could be the solution that the chemical engineering industry and academia are looking for.

Bringing Theory to Life, Anywhere You Want

AR in chemical engineering education bridges the gap between obscure theoretical contents and the real world. Imagine pointing your phone anywhere you want, and chemical plants are just one tap away. Within one tap, you will see full-scale chemical machinery come to life in 3D, fully packed with flow visualisations and reactive processes. This level of convenience not only makes it more accessible but also significantly reduces training costs.

Safe Simulation of Chemical Processes

In an industry where risks are always involved, safety is always the first consideration. In AR experiences, hazardous chemical processes are simulated and presented in a virtual space. Doing it in a virtual space not only ensures safety but also allows for the exploration of processes that would otherwise be too dangerous, expensive, or impractical to perform in the real world. As a result, AR experiences can be used to better prepare chemical engineers for hazardous situations or unforeseeable events.

Personalised Learning Experiences

For better training and learning results, chemical engineers are always pursuing more effective training methods. AR provides a cost-effective way of delivering tailored training sections to meet the individual needs of the trainees. Trainees can progress at their own pace and revisit complex topics anytime as required. This personalised approach can provide a sound understanding of the chemical processes and significantly reduce the chance of undesirable events related to human errors and insufficient training.

Real-World Impact and Beyond

The application of AR technology in chemical engineering is beyond theoretical. Higher education institutions worldwide have already integrated the curricula, and the University of Sydney is no exception. AR technology has been adapted as part of the School of Chemical and Biomolecular Engineering laboratory. Chemical engineering students can use AR to explore the internal structure of industrial equipment and the working principles behind them.

The first application of the AR experience was a digital twin of an airflow experimental rig. This rig aims to teach students the working principles of different flow rate measurement devices, including pitot tube, venturi flowmeter, and orifice plate flow meter. With AR overlays, students can now “see through” the metal construction of the rig and better understand the internal structure of different flow meters. With the integration of CFD simulation results, the invisible flow pattern becomes visible, and the principles behind different flow meters unveil themselves. The student can also find information on different parts of the rig by simply tapping it on their smartphone or tablet when needed.

Other than overlaying static information onto an experimental rig, animations in AR were also developed and used. One example is the AR experience for a laboratory-scale spray dryer. In addition to overlaying all the CFD simulation results onto the spray dryer, students can also view the installation sequence of the spray dryer as animations in AR. Going through the installation sequence in AR may never be the same as doing it in the real world, but it gives everyone an equal opportunity to do it, which is something not possible considering all the physical limitations. Besides improving students’ learning experience, AR demonstrations also help reduce financial loss and equipment downtime.

Challenges and Future Directions

While AR technology has shown great potential in chemical engineering education, the specific and diverse skill sets required for developing AR experience may significantly limit its widespread use. Unlike the more immersive virtual reality (VR) technology, which requires specific hardware, AR technology does not heavily rely on particular hardware. The “software” is the critical challenge in AR technology. Software development kits (SDK) with a graphical user interface (GUI) like Vuforia have significantly reduced learning costs for AR experience developers. In fact, all AR experiences were developed using Vuforia with the assistance of LEAP Australia. Despite the fact that the current state of the software may not be perfect, the authors believe that as technology advances and becomes more accessible, these issues are likely to diminish.

The Future of AR in Education and Training

Looking forward, AR technologies and other virtual technologies will become essential to chemical engineering education and STEM fields at large. More completed AR experiences capable of simulating manufacturing plants are already on the horizon, providing future engineers with unparalleled insight into their future careers.

Conclusion

Integrating augmented reality (AR) into chemical engineering education makes a huge leap forward regarding how cutting-edge technologies may contribute to higher education. Engineering education will be revolutionised by utilising virtual technologies to visualise abstract technical content, enhancing safety, and personalising learning experiences. As we continue to push the boundaries of teaching methods, one thing is clear: the future of education depends on adapting and integrating these technological advancements.