Guest Blog by Dr. Aakash Shaun Hurry, Edith Cowan University

What if the secret to advancing thermal performance lies in shapes that nature has refined over millions of years?

Rethinking Heat Exchanger Geometries Through Nature

My PhD research set out to answer a simple but powerful question: can inspiration from biology help us design more efficient heat exchangers? Heat exchangers are the hidden engines of modern life. From power plants and aircraft engines to data centres and electric vehicles, they keep critical systems stable by transferring heat. Yet despite their importance, most heat exchanger fins have remained unchanged for decades, typically relying on rectangular, cylindrical or elliptical shapes.

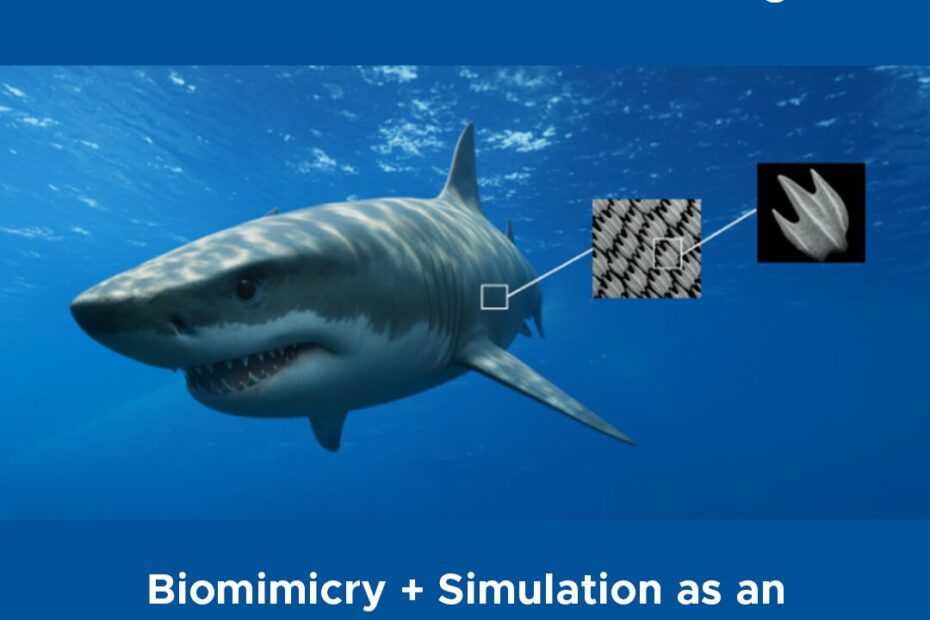

Figure 1: Illustration of dermal denticles on the shark skin.

At the same time, nature has been refining geometries for millions of years. Sharks, for example, owe their speed and agility not just to muscle power but also to their skin, which is covered in microscopic tooth-like scales called denticles (Figure 1). These denticles manipulate fluid flow and help reduce drag by delaying flow separation and inducing streamwise vortices. If evolution can shape efficient swimmers, could similar structures also help engineers improve thermal systems?

That idea became the foundation of my doctoral work at Edith Cowan University. Using a combination of CFD (Ansys Fluent), additive manufacturing, and laboratory testing. I explored how shark denticle geometry could be applied to heat exchanger fins and as surface textures, validated against experiments and ultimately optimised beyond what nature provides.

Building a Biomimetic Workflow

To move this idea from concept to reality, I developed a systematic workflow:

- Reverse Engineering: Based on published SEM and micro-CT scans, I reconstructed shark denticle geometries and translated them into parametric CAD models.

- Additive Manufacturing: High-resolution 3D printing in stainless steel produced physical prototypes.

- Benchmarking: Conventional fin designs : rectangular, elliptical and cylindrical were used as baselines for the simulations.

- Experimental Validation: A custom wind tunnel rig was designed and validated to test for pressure drop and heat transfer, with uncertainty reduced to below 3 percent.

- CFD Simulation: Conjugate heat transfer simulations in ANSYS Fluent employed poly-hexcore meshing and the k–ω SST turbulence model for robust near-wall predictions.

- Shape Optimisation: Using Fluent’s adjoint solver, I performed gradient-based optimisation to maximise heat flux while controlling drag penalties.

This approach turned biomimicry from inspiration into a structured engineering method, supported by both experimental evidence and advanced simulation.

Results that Redefine Baselines

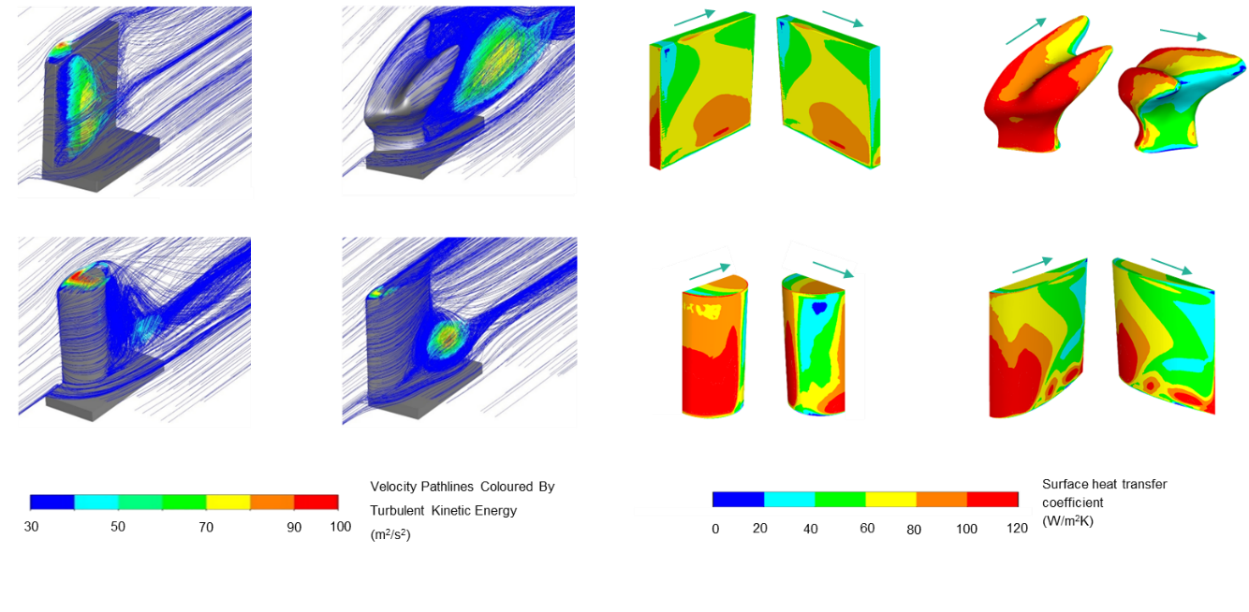

Figure 2: Numerical results indicating regions of turbulence and surface heat transfer coefficient.

As illustrated in Figure 2, the results showed clear differences between conventional and bio-inspired designs:

- Rectangular fins suffered from early separation and limited heat transfer.

- Elliptical fins reduced separation but still struggled with turbulence which resulted in a 5% decrease in Nusselt Number compared to the denticle.

- Denticle-inspired fins accelerated near-wall flow, induced vortices and significantly improved heat rejection by approximately 11% on average compared to the other fins.

- Optimised denticle fins performed best overall, achieving higher thermal performance factors while maintaining acceptable pressure losses.

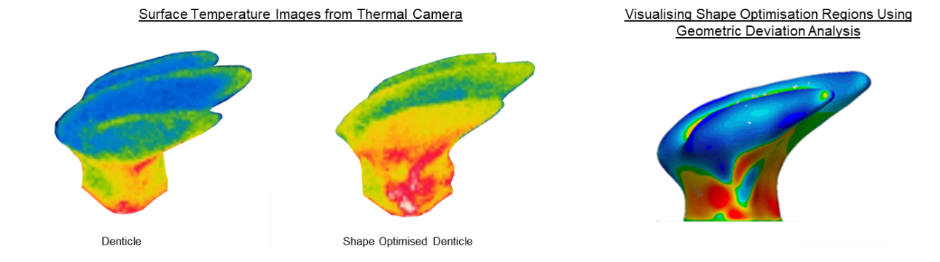

Figure 3. Thermal camera surface temperature images.

Thermal imaging validated these findings, confirming that the denticle-based designs rejected more heat than traditional fin geometries. The optimised version further improved performance, as shown in Figure 3, which highlights enhanced heat transfer regions on the shape-optimised denticle fin. This demonstrates how simulation can take nature’s solutions to the next level.

Biomimicry as an Engineering Framework

Biomimicry is often framed as “learning from nature.” It has inspired examples from the kingfisher-shaped bullet train to self-cleaning surfaces based on lotus leaves. But too often, it remains a metaphor rather than a methodology.

- My research reframed biomimicry as a workflow:

- Identify promising natural geometries.

- Reverse engineer them into digital form.

- Validate experimentally.

- Optimise with computational tools.

Nature provides the starting point. Engineering provides the means to interrogate, test and evolve these ideas into practical solutions. This shifts biomimicry from imitation to innovation.

Why This Matters

The potential impact is broad:

- Energy systems could achieve more efficient cooling in power plants and renewables.

- Data centres and HVAC systems could reduce their energy footprint.

- Aerospace and automotive industries could benefit from lighter, more efficient cooling systems.

- Further the same concepts could be extrapolated for more efficient hydrodynamics or aerodynamics on planes and submarines.

Even improvements of 10-15% in heat transfer efficiency or 20% in reduced flow resistance, when scaled across energy, transport and industries worldwide, can translate into major reductions in energy use and carbon emissions.

Publications and Recognition

This research has been published across leading journals and my doctoral thesis, each contributing to different aspects of the investigation:

- Applied Thermal Engineering (2023): Numerical investigation of the thermo-hydraulic performance of a shark denticle-inspired plate fin heat exchanger (https://doi.org/10.1016/j.applthermaleng.2023.122192)

- International Journal of Heat and Mass Transfer (2023): Thermo-hydraulic performance evaluation of a NACA 63-015 heat exchanger with shark denticles as surface textures (https://doi.org/10.1016/j.ijheatmasstransfer.2023.124591)

- Edith Cowan University (2024): Biomimicry for the shape optimisation of heat exchangers: Exploring hydrodynamic profiles inspired by shark denticles (https://doi.org/10.25958/w76m-ch95)

Collectively, these publications and my PhD Thesis highlight not only the feasibility but also the broader potential of integrating biomimicry into engineering design.

The Future of Biomimetic Design

Shark denticles were just the starting point. Nature offers countless examples of surfaces and structures optimised for fluid and thermal interactions. With advances in CFD, optimisation algorithms and additive manufacturing, engineers are better equipped than ever to explore and evolve these natural forms.

By treating biomimicry as functional modelling, we can discover solutions that not only match but surpass evolution, tailored for modern challenges.

Final Reflections

From the microscopic scales of shark skin to stainless steel prototypes tested in the lab, this research shows how evolution’s wisdom can merge with digital simulation to produce new engineering solutions.

Nature provides the blueprint. Engineering allows us to take it further.

Dr. Aakash Shaun Hurry

Edith Cowan University

If you are as fascinated by the potential of biomimicry as I am, I would welcome the opportunity to connect and discuss. Connect with me on LinkedIn.