Part 1 – Guest Blog by Julio Martins, former Aerodynamics & Cooling Lead, UNSW Redback Racing

UNSW Redback Racing is the University of New South Wales (UNSW) Formula SAE Team. Redback was founded in 2000 and since our inception, we have continued year on year to design, build and race in the Formula SAE Australasia competition. With each car, we strive for improvement and innovation, building on previous designs and advancing our knowledge into the future. We transitioned from internal combustion to electric in 2019 with our first dynamic electric vehicle RB21 being completed over 2 years for the 2022 competition. In 2023, we designed and manufactured our first EV in a single year as well as the first full aerodynamics package since 2018. RB23 competed in the 2023 Australasia competition, placing 2nd overall in the EV category and matching our best ever result.

Team Picture 2024 with RB21 (Left), RB23 (Right) and RB24 (Middle)

In 2024, we celebrated our Silver Jubilee (25th Anniversary) and set our sights on making RB24 something special, advancing in design, manufacturing and overall presentation. The aerodynamics, cooling, and composite department set our goal to manufacture the most aerodynamically and structurally complex, highest performing, and most well finished aerodynamics and bodywork package in team history. The aerodynamic design would be rigorous and aim to fully characterise the performance of the aerodynamics package with the goal to further improve integration with Vehicle Dynamics, to ensure the package improves vehicle performance and ultimately to grow our understanding and knowledge of the aerodynamic behaviour of RB24 to improve in future design.

I joined the team in the aerodynamics department at the start of 2022 and worked on the cooling system and manufacturing of RB21. I was then selected as the aerodynamics and cooling lead for 2023, running all the CFD and leading the design and manufacturing of RB23’s aerodynamics and cooling package. In 2024, I took a step back from lead to focus on my honour’s thesis: Design and optimisation of an FSAE focused venturi undertray with CFD and wind tunnel validation, as well as continue to perform the CFD analyses of the aerodynamics package.

Reviewing the team’s Aerodynamic approach over recent years

RB21 (2020-2022)

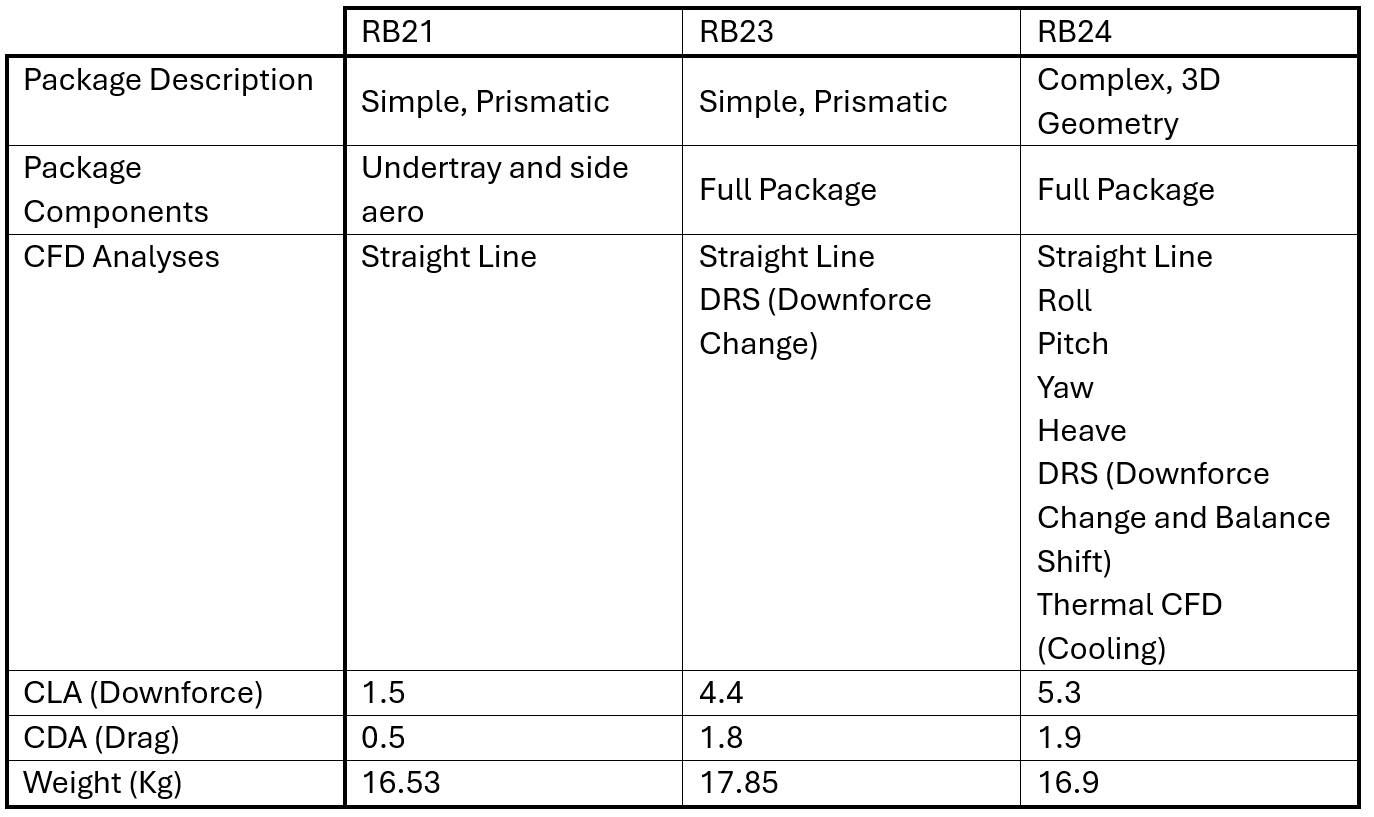

Over the past 4 years, our approach to aerodynamics has changed substantially. The covid pandemic saw a large loss in aerodynamic and composite knowledge within the team as well as funding which drastically limited scope for aerodynamics both in terms of design complexity and maturity but also by what was able to be manufactured. The transition to our first dynamic electric vehicle and low knowledge in the EV space also reduced aerodynamic scope due to fears of increased drag and limited battery capacity. Furthermore, the main priority for the team was to get the car running. For these reasons, RB21 (2020-2022) saw a reduced aerodynamics package comprising a central underfloor and side mounted airfoil stacks without any front or rear wings. The accumulator used internal fans for cooling while the motor and inverter each had a side mounted radiator within side-pod ducts above the side aero stacks. The package was designed and manufactured over 18 months and produced a CLA of 1.5 and a CDA of 0.5 while weighing 16.53kg for the underfloor and side airfoil package.

RB21 at Winton Raceway for the 2022 FSAE-A Competition

RB23 (2023)

With the EV knowledge we gained from RB21 and the new battery cells obtained at the end of 2022 for future cars, we set our goal on improving upon RB21 rather than outright revolution. “Keep it Simple, Do it Right” was the team goal. The new battery cells and improved dynamic EV understanding allowed us to increase scope for the aerodynamics package to move to a full aerodynamics package on RB23, comprising a central underfloor with side airfoil stacks coupled with a front and rear wing. It would be the first full aerodynamics package designed and manufactured by the team since 2018 and also the most complex at the time. This would be no easy feat, with further knowledge (member) loss at the end of 2022 and even more reduced funding. For this reason, RB23’s package was designed with only prismatic (straight) airfoil elements to reduce manufacturing complexity. Large wings like the rear wing and side aero main elements were spar and rib designs (carbon tube spars with laser-cut plywood ribs) to reduce weight and layup complexity. The cooling package on RB23 also changed, with the radiator for the motor and inverter moving to the rear of the car while the accumulator remained fan forced. RB23’s aerodynamics package was designed over 3 months and ultimately produced a CLA of 4.4 and a CDA of 1.8 in a straight line. The package was manufactured over 3 months with leftover carbon fibre from 2019 and $2000 in budget and produced a full aerodynamics package weighing 17.85kg. This resulted in a near 3 times improvement in downforce with an increase in weight of only 1.3kg over RB21.

At competition, we achieved 2nd place overall in the EV category, achieving 2nd in Endurance, 3rd in Autocross and 3rd in Business Presentation. It was an achievement we were all incredibly proud of and showed the rapid growth in knowledge and skill within the year for the aerodynamics department as well as the wider team. Management of the accumulator thermals during Endurance was however a critical issue during the competition for RB23, where insufficient accumulator cooling design caused cell temperatures to rapidly approach the rules-mandated maximum of 60°C. This forced the driver to back off on pace and reduce power output to bring cell temperatures back down, resulting in significant lap time increases and ultimately costing us competition points.

RB23 on Library Lawn at UNSW for Media Day 2023

RB24 (2024)

Moving to RB24 and our 25th anniversary, the goal for the aerodynamics, cooling and composites department was to build upon all the knowledge we gained from RB23’s package to further advance and improve the aerodynamics package for RB24 as well as push to enhance the finish quality of the composites. The cooling package focused on reducing weight of the motor and inverter cooling loop while improving the cooling of the accumulator using stronger fans as well as RAM air ducts to maximise cooling performance. The increase in our knowledge across aerodynamic design and composite manufacturing of RB23 allowed for a more complex full aerodynamics package to be designed and manufactured, comprising 3D curved elements on the front and rear wing as well as a single piece side venturi tunnel style undertray which was designed as part of my honour’s thesis.

RB24 Front Wing Picture Showing 3D Airfoil Elements

RB24 Single Piece Side Venturi Tunnel Undertray

We also pushed to better simulate the package, not only running “straight line” simulations used for rapid design optimisation, but also fully characterise the package performance in Roll, Pitch, Yaw, Heave and DRS settings to better understand the dynamic behaviour of the package and its interaction with kinematics and vehicle dynamics. Over the course of design and testing for RB24’s aerodynamics package, over 1.8TB of CFD data was produced through over 70+ simulation runs for just the external aerodynamic analysis. Further thermal CFD analyses were performed by Marc Morabito to analyse the cooling performance within the accumulator which he is doing as part of his Honour’s thesis. The accumulator managed to maintain a maximum temperature of 45 degrees Celsius during endurance, showing a clear improvement over RB23. Overall, RB24’s aerodynamics package produced a CLA of 5.3 and a CDA of 1.9 from a full package weighing 16.9Kg.

RB24 Outside Law Library at UNSW for Media Day 2024

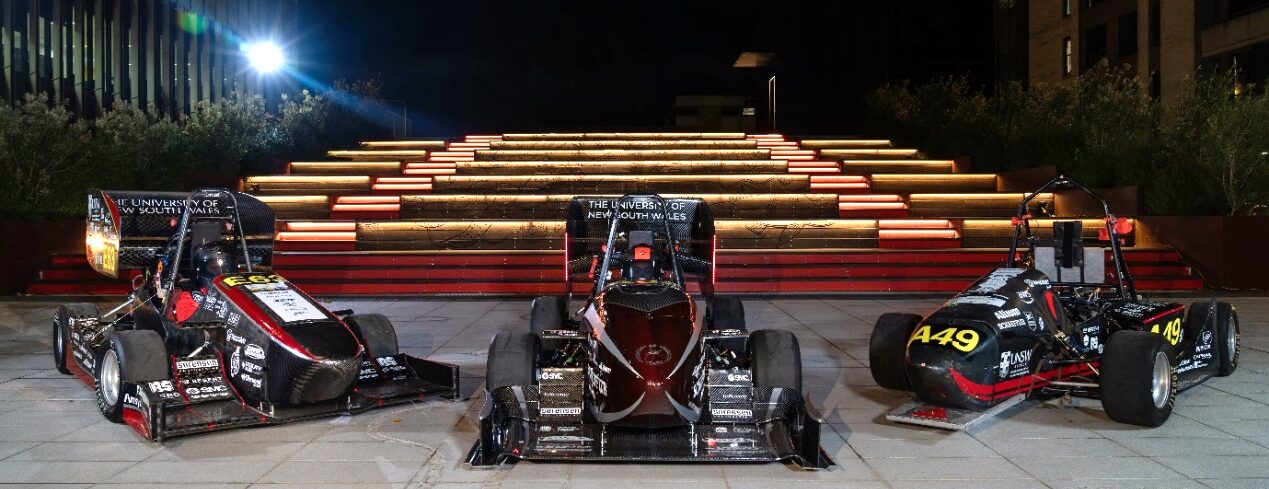

Picture of RB21 (Right), RB23 (Left) and RB24 (Middle) for Media Day 2024 showing Aerodynamic Package Progress

How has simulation played a role?

The use of Ansys CFD simulation, specifically Ansys CFX has been crucial to the design of the aerodynamics and cooling package. The team up till the end of 2024 has been using Ansys CFX but will be transitioning to Ansys Fluent over 2025 and into the future.

CFD analyses are used in various ways throughout the design period of the aerodynamics packages, with straight line half car (symmetry) simulations used for rapid iteration and optimisation during design but can also be used for Pitch and Heave characterisations due to symmetry being maintained. Larger and more computationally intensive simulations which simulate the car without symmetry are used for the characterisation simulations for Roll and Yaw. These larger simulations require upwards of 200GB of RAM to simulate while in the case of the parametrised Yaw simulation, taking a full week to simulate from 0 degrees to 14 degrees of Yaw (1-degree increments).

CFD is a vital tool for aerodynamic design and the most important part is not simply in running the simulations but knowing how to post process and analyse the results, what data is useful, how to use it and what it means. This not only relates to understanding the flow field around the car and how the package generates downforce but more importantly, diving deeper into the countless results provided by CFD for a single simulation and what these mean in the context of vehicle dynamics. Making links between simulation sweeps, plotting charts of performance curves rather than looking at single simulations at a time. For myself, the key to vehicle aerodynamics is not only how much downforce and drag its generating, but more importantly, understanding how the package performance and balance changes as the vehicle moves and corners.

During the design of RB24, we were able to utilise LEAP products to better understand the thermal management requirements of the accumulator. Utilising Ansys CFX, we created a full-scale 3D model of the accumulator to simulate the performance of a forced-convection active cooling system. Using a high-resolution mesh with inflation layers, we were able to simulate the complex turbulent flow structures inside the accumulator and the convective heat transfer mechanisms between the fluid-solid interfaces. Taking experimentally obtained data from track-testing of the car, we were able to determine the ohmic, polarization, and reactive heat generation of the cells over a lap and incorporate it into a steady-state simulation to simulate the cells thermal output. By utilising the parameterisation tool within Ansys CFX, we were able to automate the simulation process to run multiple iterations at varying flow rates to determine the target mass flow rate through the accumulator that would sufficiently cool the cells. Validation from on-track testing of RB24 showed that the cooling system functioned effectively. Cell temperatures reached an equilibrium at a ~20°C ambient air temperature delta, in line with our simulation results. This was a significant improvement over RB23, allowing us to carry out our endurance stint at the 2024 FSAE-A competition without concern of high accumulator temperatures.

A Brief Understanding

The performance and behaviour of RB24 was fully characterised in Roll, Pitch, Yaw and Heave as well as the balance shift with changing DRS settings. This provided us with valuable data to not only analyse the downforce and drag variation in different cases but also allowed us to quantify the aerodynamic balance shift of the package in all conditions. It also allowed us to determine the dynamic behaviour of the package well beyond what we had for RB23. One metric I like to provide about RB24’s package is that it makes the same amount of downforce at 7 degrees of Yaw as RB23’s package made in a straight line. It was a step up over RB23’s package in every aspect but I’ll touch more on the specific results in Part Two of this series.

Stay tuned for Parts 2 and 3 in this blog series which will dive deeper into Redback Racing’s CFD simulation results with a focus on the full characterisation of RB24’s aerodynamic behaviour as well as flow visualisation of the improvements of RB24 over RB23.