LEAP recently moderated a live panel discussion on materials calibration for discrete element method (DEM) modelling of bulk solids and had the privilege of hosting industry leaders Daniel Grasser, Consulting Engineer at Tunra Bulk Solids and Richard Elliott, Technical Director – Bulk Handling at Rockfield Technologies. They were joined by DEM specialists from LEAP: Angelo Christakakis, Application Engineer & Technical Lead – DEM as well as Josh Hately, Engineering Solutions Manager, who moderated the discussion.

Here is some background to the significant experience of the panellists:

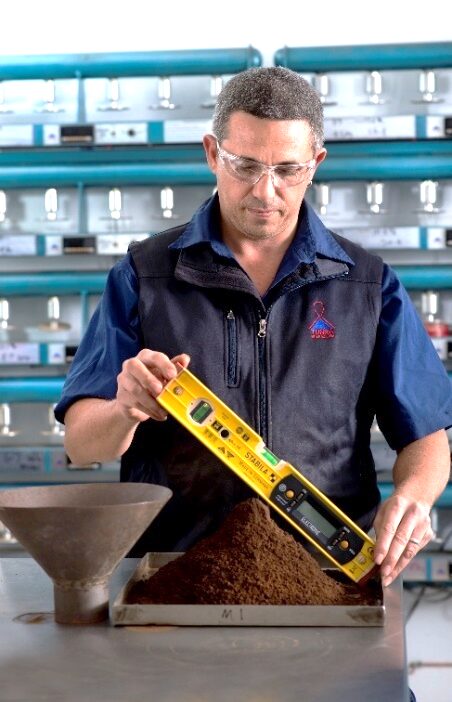

Daniel Grasser, Consulting Engineer, TUNRA Bulk Solids

Daniel is a mechanical engineer with interests in bulk materials handling and wear resistant materials. He obtained a PhD from the Institute for Frontier Materials (IFM), Australia, and was then appointed as an Associate Research Fellow, working in the field of wear testing of metals.

In 2023, Daniel joined TUNRA Bulk Solids as a Consulting Engineer. He is particularly interested in DEM modelling of abrading and impacting particles and the resulting wear. Daniel is also interested in experimental validation methods and DEM calibration, especially for cohesive materials.

Richard Elliott, Technical Director – Bulk Handling, Rockfield

Richard is a specialist in bulk materials handling with expertise in conveyor systems, transfer chute design, and mine/port infrastructure. He has led the engineering and optimisation of large-scale conveyors and transfer stations for major mining clients, delivering solutions across debottlenecking studies, DEM analysis, liner selection, rotable chute design, and root cause investigations into belt drift, spillage, blockages, and wear. He has also delivered upgrades to ship loaders, stackers, reclaimers, and impact plates, ensuring improved capacity, reliability, and maintainability at ports in Australia.

He has a focus on improving material flow and belt loading, extending wear life, and enhancing safety across conveyor and transfer systems and has been a Rocky DEM user since v2 in 2013!

Angelo Christakakis, Application Engineer & Technical Lead – DEM, LEAP Australia

Angelo works as an Application Engineer at LEAP Australia, specialising in computational engineering and with a focus on addressing bulk materials handling challenges using DEM, FEA & SPH. He has worked on a diverse range of projects such as optimising flow through transfer chutes through to reducing system power draw in comminution processes. During his team at LEAP, Angelo has worked closely with a large number of Ansys and Rocky DEM customers around Australia and New Zealand.

In case you missed the live panel, here are the key takeaways from this engaging conversation.

What Is Materials Calibration and Why Is It Necessary?

Daniel Grasser kicked off the discussion by explaining that materials calibration in DEM involves adjusting models to accurately represent bulk flow behaviour in various conditions, especially in mining. “Most of the time, it’s about capturing the bulk flow rather than being interested in single particles,” he explained. “The process requires experimental data for validation, helping connect microscopic properties—like particle interactions—to macroscopic behaviours in real-world applications. Once we have the calibration data or experimental data, we can start calibrating our model. For example, starting with the bulk density and the interaction between the particles.”

Adding to this, Angelo mentions that DEM includes “models that can consider real particle shapes, and sizes down to the micro or even nano scale”. However, “we face challenges in terms of computational feasibility, so we need to make choices based on balancing accuracy against practicality”, while fulfilling the needs of the simulation. To this end, “materials calibration is necessary for every DEM analysis because of the usage of idealized, or simplified, physics and contact models” which are used to represent systems of bulk materials. At its core, materials calibration is thus the process of connecting “microscale model parameters back to what’s happening at the macro scale”, so that the model can sufficiently characterise material flowability and responses to external loads.

Key Material Properties for DEM Calibration

A critical part of the discussion revolved around which material properties are vital for effective DEM calibration. Daniel emphasised the importance of bulk density, particle shape, and size. “All properties matter, but bulk density is particularly crucial,” he stated. “The shape and the size are also important, and for new users it may be a bit confusing, that the particle size in DEM is usually much bigger than what we see in reality.” He also highlighted the need to consider the specific context — the required particle sizes for problems associated with cohesion may differ from those for problems with wear.”

Richard echoed these sentiments, urging participants to consider the intended application. “Before you calibrate your material, it’s essential to understand what you are trying to achieve.” he said. “Are you trying to calibrate one material or a range? Understanding the variability in the materials is essential for recognizing what might be the worst case. The calibration could vary significantly between free-flowing and sticky materials, which may introduce challenges particularly in designs involving blockages or wear.”

From a simulation perspective, Angelo noted that the key material properties and model parameters are those that fundamentally “characterize the bulk material.” He begins by discussing particle shape and size representations. “As modelers, it’s important for us to make a decision on how we want to characterise particle shape,” he said, “as this property can have a significant influence on the material’s bulk strength. For example, high-aspect-ratio, jagged, or blocky particles can introduce interlocking effects that increase bulk strength.” Angelo also pointed out how particle-size distribution controls the effective resolution in a DEM model. Coarser or upscaled particles will reduce particle counts across spatial gradients and “smoothen or smear” flow features, risking failure to resolve critical behaviours.

Testing and Metrics for Calibration

Josh shifted the conversation to the metrics and tests that are most useful for DEM materials calibration.

Richard has extensive experience in calibrating for cohesive sticky materials and noted that, in his experience, using shear cell testing provides valuable data. “I have been using simulated shear cells for over a decade to measure flowability because they reveal how materials behave under various conditions,” he noted. “An angle of repose test is simple but has many limitations; it doesn’t capture how the material behaves under different consolidations. Shear cells were developed to do just that.”

For those dealing with existing materials, Daniel advised leveraging site-specific data. “Observing real-world behaviour can yield valuable insights into how to calibrate and validate your model, particularly when looking for blockage causes or wear hotspots,” he suggested.

Practical Calibration Workflows

At the heart of effective calibration is a well-structured workflow. Richard usually recommends establishing material properties through controlled tests before simulating conditions. “I usually establish what the material properties are that I’m trying to replicate at usually two bookends: a free flow or a sticky case,” Richard stated. He also noted that he tends to read the bulk density as a result of the simulation, rather than setting it outright. “Choosing the adhesion model is number one, and I usually use different static and dynamic friction, with the static friction usually set higher,” he added.

Angelo added to discuss the challenges of implementing a single, unified calibration process given limitations in available material data or in what could feasibly be obtained. He advised one practical workflow: calibrate dry, free‑flowing samples first, then calibrate wet, sticky samples to isolate cohesive properties. He also noted that the required level of detail in calibration depends on the goals and type of analysis. “You can still extract value from simulations,” he said, even with limited material data, “particularly if the study is comparative in nature.” Comparisons and conclusions remain valid across design iterations, provided the material model is kept consistent.

Capturing Worst-Case Scenarios

In discussing worst-case scenarios, Richard offered a practical approach: “Ensure your model can replicate the problem at hand. If you can accurately model the existing flow issues, you have a strong foundation for assessing improvements.” Richard replied, “In most industrial applications, you’re often asked to run a DEM simulation to correct or assist in root cause analysis for an existing problem. You know your model is good enough to provide insights when it can replicate that problem. If you can accurately model the existing flow issues, you then have a strong foundation for assessing improvements. But always consider that the same material might behave differently in various applications; adjustments may be needed for different conditions.”

Daniel stressed the importance of understanding the application context to identify which scenarios require calibration. “It makes sense to calibrate for the worst-case scenario, for example when looking into problems with very cohesive materials, because a robust design should handle other less severe cases as well,” he said.

Key Takeaways for Simulation Practitioners

To encapsulate the insights shared during the panel, here are few takeaway points that the panel asks Simulation practitioners to consider:

- Diverse Calibration: Don’t just calibrate for one material type; consider a range for more robust results. Richard adds “if you’re calibrating cohesive sticky materials, use shear cells instead of angle of repose.”

- Testing Methods: Ensure that you have access to a comprehensive set of reliable experimental data for the calibration of your DEM model. Daniel agrees that “an angle of repose test alone is just a starting point, additional testing is needed to calibrate a DEM model.”

- Understand Your Process: Simulations must be grounded by a clear understanding of the real process being modelled. Angelo concludes with “Understand the process you’re trying to simulate first. This understanding will dictate what data is critical for calibration.”

Closing Thoughts

The DEM calibration process is complex, but with a thoughtful approach that includes rigorous testing and an understanding of the materials involved, practitioners can enhance the effectiveness of their models significantly. We encourage anyone interested in this field to join us at the upcoming International Conference on Bulk Materials in Fremantle (7th – 9th July, 2026) or attend our upcoming LEAP Technology Days | Simulation in Melbourne (12th November 2025) and Adelaide (27th November 2025) for further discussion.

A big thank you to our guest panellists Daniel Grasser and Richard Elliott for sharing their expertise, and to everyone who joined us for this enlightening discussion. If you have further questions or would like to continue the conversation, please feel free to reach out!