In this post we delve into the world of Model-Based Definition (MBD) and demonstrate how to embed annotation data directly into your 3D CAD models. As part of our Creo Best-Practices webinar series, Ben Muston, Senior Application Engineer at LEAP recently took a deep dive into MBD, explaining 3D GD&T, semantic references, and leveraging annotation planes. Read on and watch the highlights of Ben’s presentation to learn how your team can streamline design-to-manufacturing workflows without relying on 2D drawings.

Ben begins by explaining how MBD defines the source of product and manufacturing information (PMI) as the 3D model, effectively replacing the 2D drawing as the ‘single source of truth’ for your design data. Watch the clip below to learn the benefits MBD brings and how it can support digital continuity across the product lifecycle.

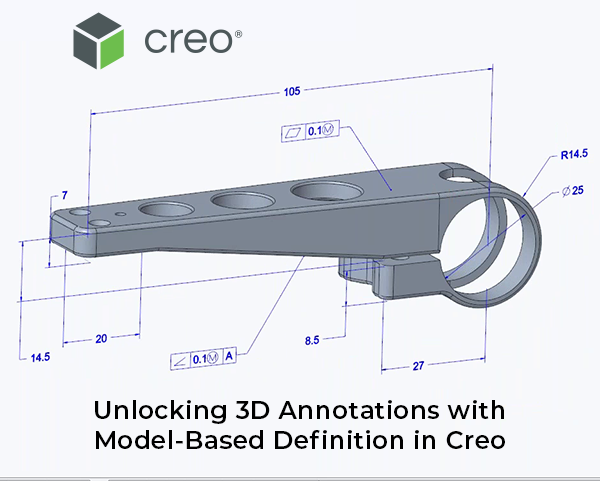

Next, Ben takes a deeper dive into the core concepts of the MDB approach, starting with annotated 3D models. By including and managing all design data such as GD&T, dimensions, notes and symbols through annotations tied directly to model geometry, there is no ambiguity in manufacturing intent. He then goes on to explain how combined states allow you to save views with specific orientations and annotations, and tailor views for different roles, for example for inspection or assembly.

Watch the clip below to learn more about the core concepts that form the basis of MBD and the MBD tools available within Creo.

In the next clip, Ben provides a live demonstration of how to create annotations linked to a 3D model within Creo and how to set up, link and navigate between different annotation views.

To finish up, Allan Thompson, PTC Technical Manager at LEAP discusses MBD beyond Creo – how MBD data can feed downstream activities and disciplines like manufacturing and technical illustrations. MBD data from Creo can flow into Windchill to automate the creation of visual BOMs and configuration information and provides access to rich visual product data to improve visual-decision making.

Allan also discusses the benefits of model-based PMI to manufacturing planning and how MBD data can be exported to 3rd party tools such as Theorem and Capvidia.

We trust you found this information helpful. For more Creo Best Practices articles, or to request specific topics that you would like us to cover in the future, visit our website.

In the meantime, if you require any assistance with your modelling or just have a question about Creo, please reach out to the LEAP PTC team.