Explore related products

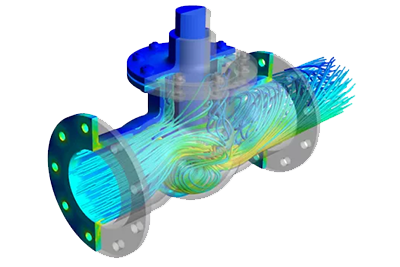

Ansys Fluent

Ansys Fluent is the industry-leading fluid simulation software known for its advanced physics modelling capabilities and industry leading accuracy.

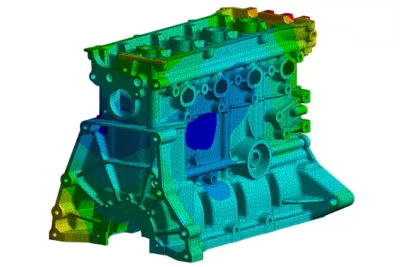

Ansys Mechanical

Structural analysis with Ansys Mechanical provides robust general purpose stress, thermal, modal and fatigue simulations for fast and accurate solutions.

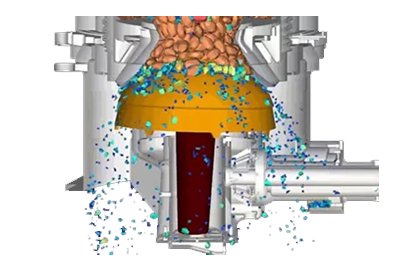

Ansys Rocky

Rocky DEM is the industry-leading discrete element method (DEM) software used for particle dynamics, simulating the motion of granular and discontinuous material.

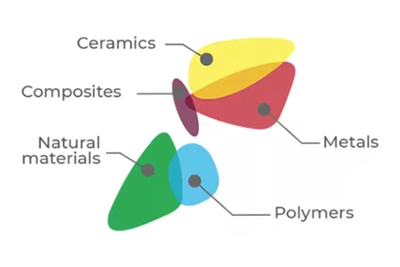

Ansys Granta

Ansys Granta is a scalable solution to create, control and store your company’s valuable material data, enabling you to capitalise on your organisation’s Material Intelligence.