Magnetic Components

Design & simulation solutions for magnetic components.

Magnetic and inductor components make up for billions of dollars in market value each year and are a prominent player in electronics product design. The ecosystem is complex reaching from simple materials to properties and shapes integrated into products. The design of Discrete Inductors, EMC related components, Filters and electric Transformers require fast design cycles for products with fast turnaround and simulation plays a big role in not only sizing processes but also testing the component in the intended system.

Nowadays, the performance of magnetic components like indictors and transformers are seen to be more critical as they are linked to the strict requirements in functionality of the overall system for power electronics such as power conversion, charging applications and control.

Validation of Inductor Designs

Inductances are added to store energy in electric circuits. This concept is often used to produce DC current in switched mode power supplies, or to remove ripples from direct current output via filters and chokes. It is also utilized to simply tune for optimised power output in power and radio frequency applications.

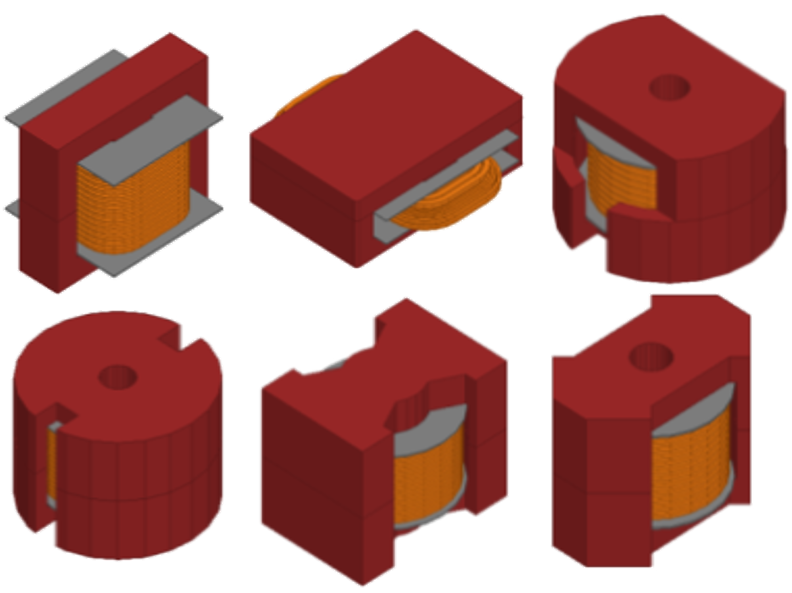

Inductors are usually assembled from a core – which are standardised but come in many different shapes – with a wound conductor and in some cases a bobbin.

Analytic calculations can guide design processes, 2D and 3D simulations give insights on what designs will provide the highest performance for an application regarding a specific converter topology.

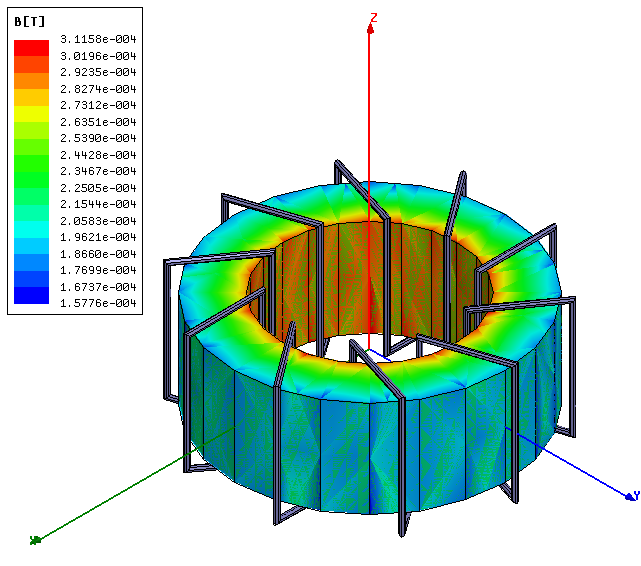

For conventional and unconventional inductors including multiple materials simulation can accurately determine the magnetic saturation, loss figures driven by proximity and eddy current effects. A virtual test can determine output waveforms and inductance values calculated.

Parametric studies allow for the calculation of LI-curves.

Predicting Electric Transformer Performance

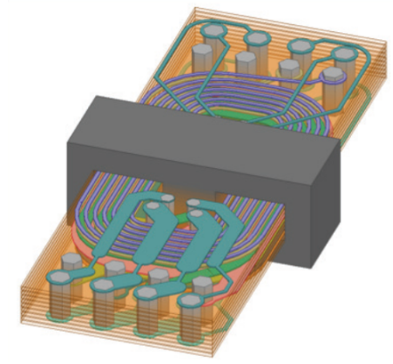

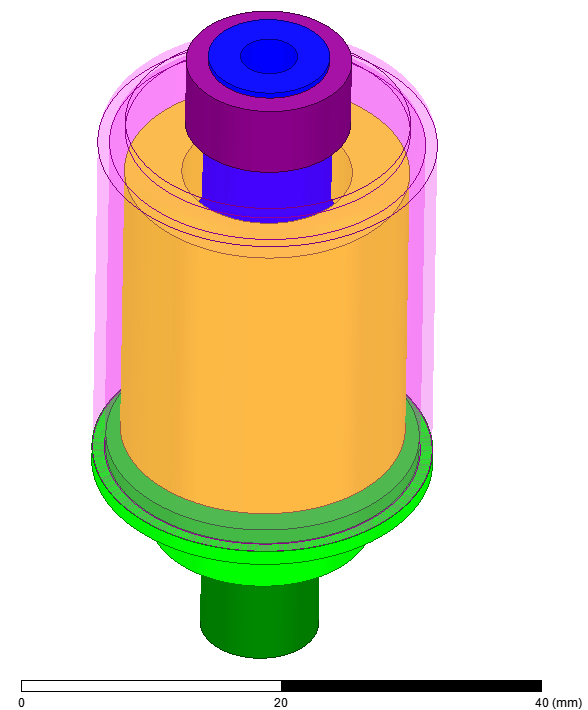

Low-loss designs with reduced heat generation, low acoustic noise are advantages of electrical transformers. Those components are using in applications like LED drivers. Planar electronic transformers integrated into PCB provide low profiles, high heat dissipation and an increased efficiency.

PCB integrated electronics transformer

While EDA tools such as Altium Designer support the design of those transformer types, Ansys provides a full design workflow from automised geometry generation to full sizing and material selection. This workflow determines electromagnetic performance like losses and impedances but also multi-physics solutions such as thermal performances.

Test Regimes for Power Transformers

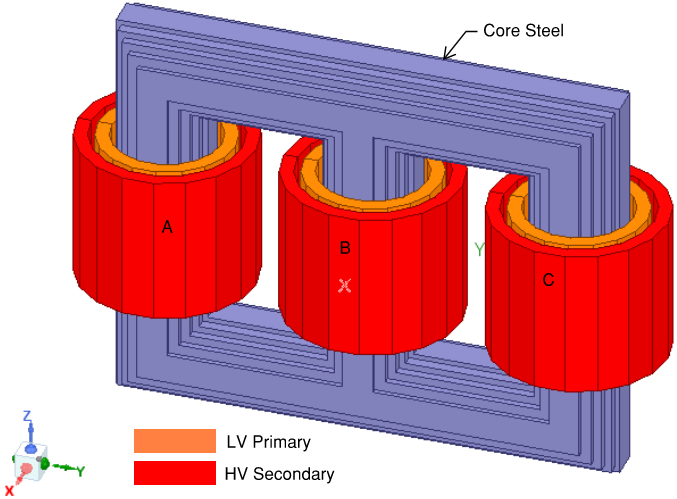

Power transformers are an important requirement for the utilisation of electrical energy. Based on Faradays induction law, 1889 Dolivo-Dobrovolsky invented the three-phase transformer using magnetic linkage of three strand fluxes.

The large power and voltage ranges require an advanced development process for design and material selection. The reduction of losses and increasing reliability are more important goals today than ever.

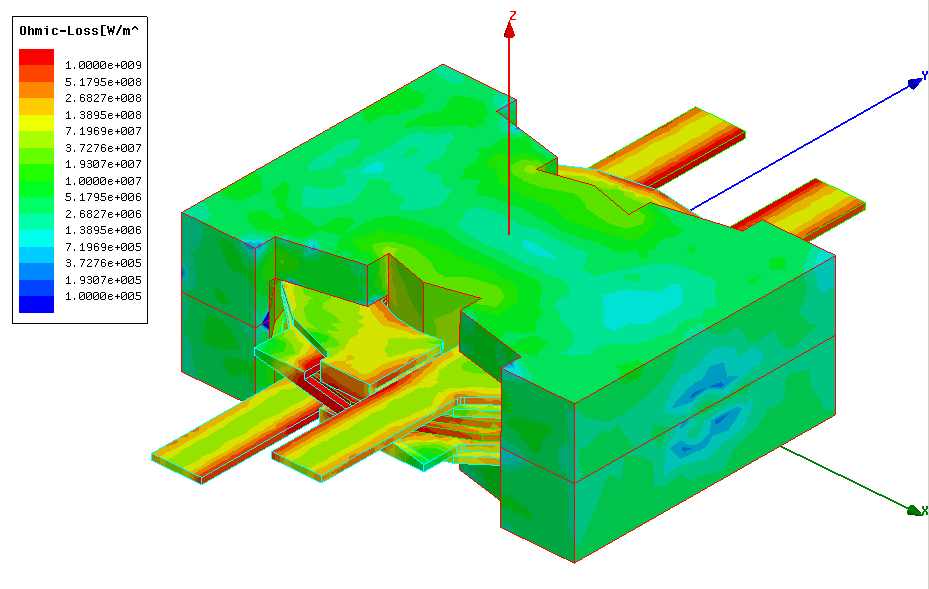

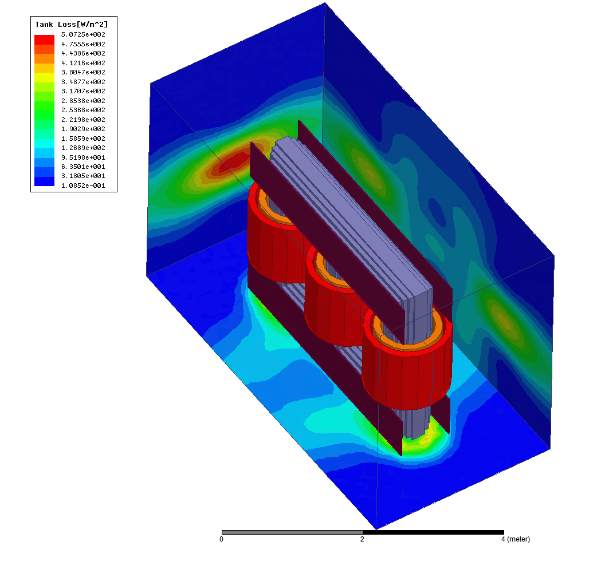

Power transformers can be tested across a field of various type tests in simulation tools covering one or more physics.

Beginning with the magnetic design simulation can answer questions around magnetic field strength H, core- and stray losses on transformer tank and structural components Busbars can lead to additional tank wall losses.

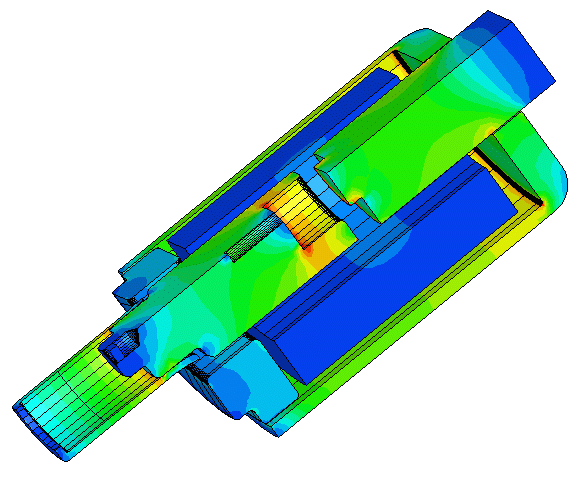

Component Design for Magnetic Switches

Electro-mechanical actuators are devices intended to move objects and are often using in automotive or industrial applications to open or close vales.

Want to learn more about LEAP’s solutions for Electronics & Electromagetics applications?

Complete the form and one our experts will contact you to discuss your needs.