Our exploration of Ansys Discovery’s capabilities now shifts from general 3D geometries to a specialised yet widely encountered case: axisymmetry. Many essential components such as pipes, flanges and pressure vessels, exhibit rotational symmetry. In this section, we’ll examine Discovery’s performance on axisymmetric problems using two established NAFEMS benchmarks, LE7 and LE8.

LE7 – An Axisymmetric Hemi-Spherically Capped Cylinder

Spherically capped cylinders are a fundamental geometry in pressure vessel design, commonly seen in applications such as gas storage tanks. Their structure offers exceptional load bearing capacity and promotes uniform pressure distribution along interior surfaces. Beyond storage tanks, this geometry proves valuable for systems where pressure must be maintained, from hyperbaric chambers to autoclaves and more.

What are the unique features of NAFEMS LE7?

Autoclaves typically make use of axisymmetric cylinders with spherical caps as seen here (Source: Southern Biological)

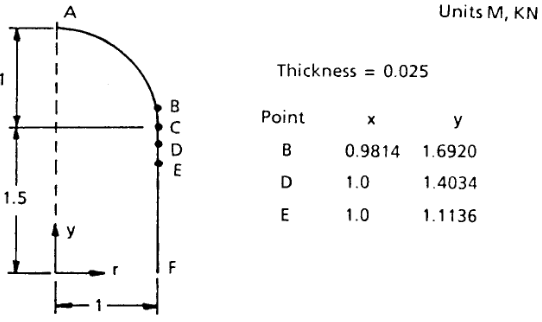

This benchmark investigates Discovery’s accuracy in modeling thin, axisymmetric shells subjected to internal pressure. The test geometry is comprised of a spherically capped cylindrical shell, with a body length of 1.5 meters and spherical end cap with a 1 meter radius. The shell maintains a consistent thickness of 0.025 meters throughout.

FEA schematic for LE7, taken from The Standard NAFEMS Benchmarks

The top of the cylinder is constrained at point A to allow only axial translation. Likewise, at point F, movement is restricted to only radial translation, with no axial translation permitted. An internal pressure of 1 MPa is applied on the interior surface. The goal is to determine the axial stress, σyy, at point D on the outer surface, and compare it to the theoretical value of 25.86 MPa.

How are we setting this up in Discovery Explore?

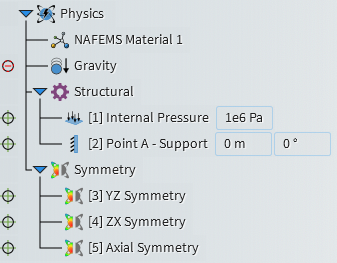

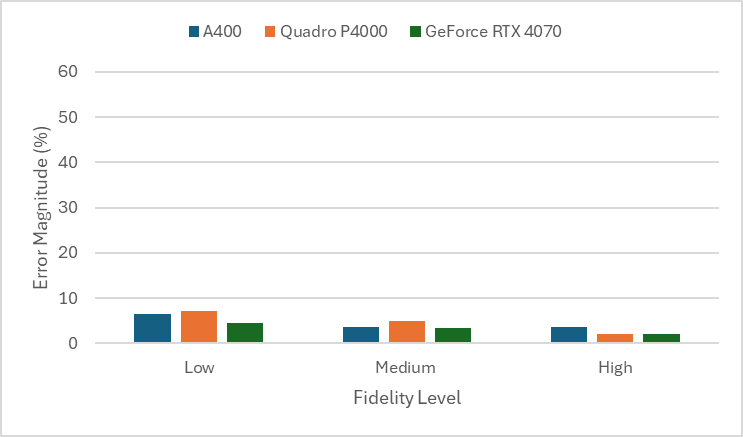

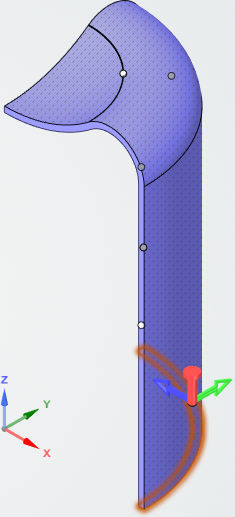

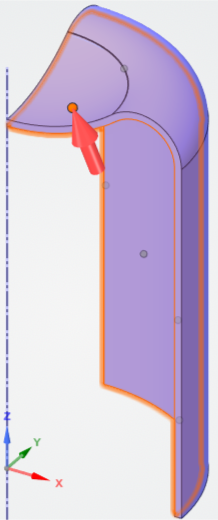

For this benchmark, we modelled a quarter of the full geometry, using symmetry to reduce computational effort. A symmetry constraint was applied to the bottom axial face, mirroring the way point F’s axial movement would be restricted in an axisymmetric simulation. Additional symmetry constraints were placed along the YZ and ZX planes. Below, you will find both the complete Discovery physics tree and the FEA model for reference.

LE7 Results

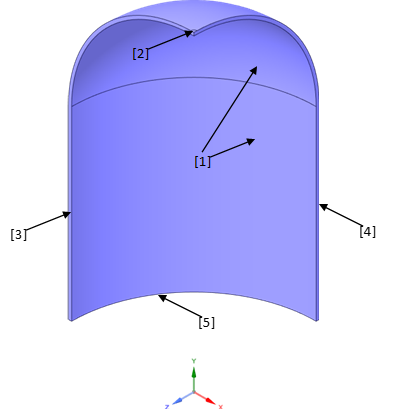

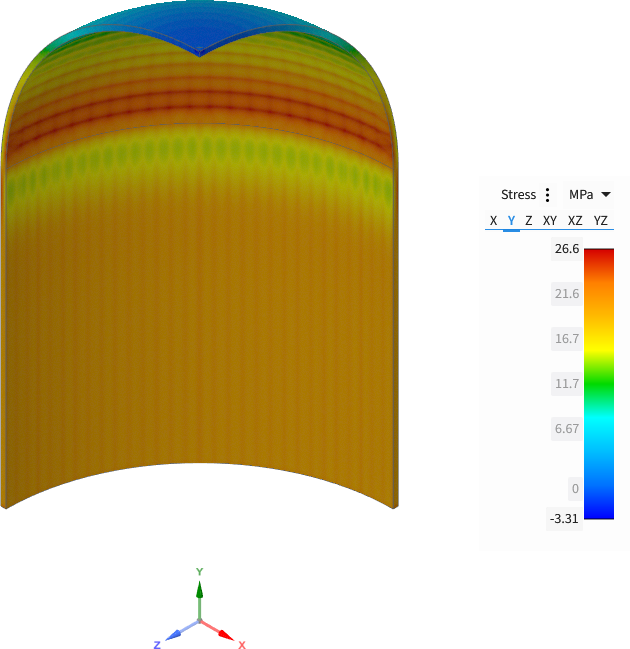

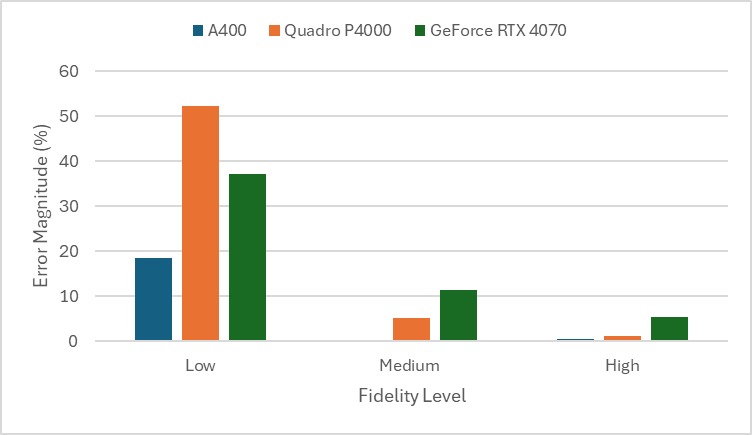

The results here are impressive, with the high-fidelity option underpredicting the stress by only 2%. Considering that axisymmetry was mimicked with 3D elements, this level of accuracy is noteworthy. Stress results from all the tested graphics cards are shown below, along with a contour plot of the stress field.

It’s worth mentioning that the stress contours look quite banded in this case. This effect is likely due to the way the mesh discretises the geometry. In theory, a linear elastic material under these loads should display smoother contours. To get a single error value for comparison, we’ve averaged the stress results from a thin ring around the circumference at the height of point D.

LE8 – An Axisymmetric Curved Top Cylinder

This next benchmark takes the LE7 geometry and increases the complexity. Instead of a simple hemispherical cap, it now has a smooth, concave dip. Although unique, its distinctive shape proves to be useful in many practical applications, closely resembling the punch and die profiles often used manufacturing.

What are the unique features of NAFEMS LE8?

These jewellery stamps showcase where these types of real-world applications can arise (Source: CraftToolPro).

This benchmark is designed to test how well Discovery can resolve complex and smooth geometries. Particularly, in capturing stress distributions across rounded parts, from concave to convex surfaces.

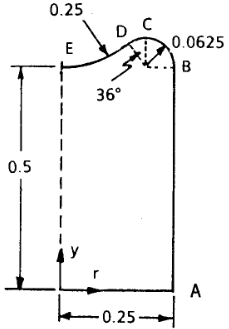

The shells in question consist of walls that span up to 0.5 meters long with a thickness of 0.01 meters. Its top surface is formed by the intersection of two circles, with radii of 0.25 meters and 0.0625 respectively. The schematic from NAFEMS is displayed below.

This geometry uses boundary conditions similar to those in LE7 benchmark: point E is restricted to axial translations only, while point A is limited to radial translations. The goal is to evaluate the tangential stress, σtt, at point D on the outer surface of the shell under a 1 MPa internal pressure. Theoretical results predict a tangential stress of 94.55 MPa at this location.

How are we setting this up in Discovery Explore?

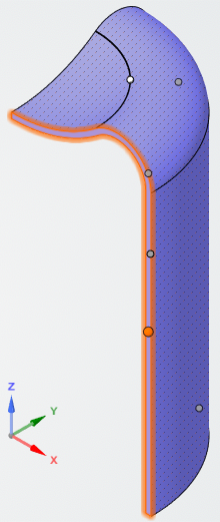

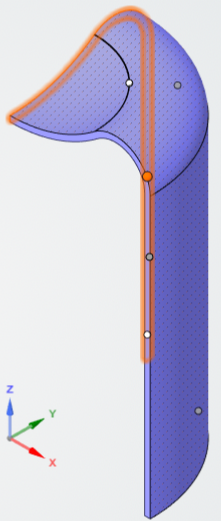

Once again traditional symmetry can be leveraged to create a quarter model of the geometry. Symmetry boundary conditions are set on the XZ and YZ planes while the bottom axial face was fixed in translation along the axial direction. The load of 1 MPa pressure condition was applied to all the internal faces and the setup for these boundary conditions is shown below.

From left to right we have, symmetry on the XZ plane, symmetry on the YZ plane, fixed translation in the axial direction, and an internal 1 MPa pressure condition.

LE8 Results

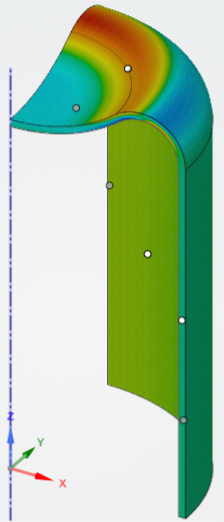

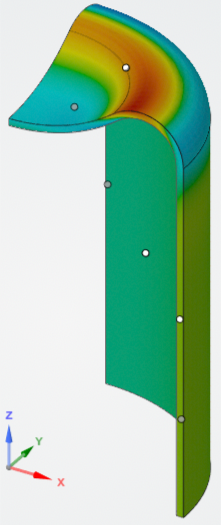

The target value we are trying to extract here is the tangential stress on the cylinder. Since Discovery operates in Cartesian coordinates, there are two methods to obtain the tangential stress:

- Extract the full stress tensor at point D in Cartesian coordinates and use a coordinate transformation to get the stress tensor in a cylindrical coordinate system.

- Alternatively, use the value of σxx or σyy on the YZ or XZ plane, respectively. On these planes, the value of stress in σxx or σyy is equal to the tangential stress, σtt.

The stress distributions of σxx (left) and σyy (right), which should be equivalent to σtt on the YZ and XZ planes respectively.

The results from this benchmark highlight how Discovery can obtain accurate results even without idealised modelling. At higher fidelities, the results are very close to theoretical values. This is especially noteworthy considering it’s a 3D solid model representing an axisymmetric case.

More in this series:

NAFEMS Discovery Benchmark Series – Part 1: Introduction

NAFEMS Discovery Benchmark Series – Part 2: Pressure Plates

NAFEMS Discovery Benchmark Series – Part 3: Simple Geometries

NAFEMS Discovery Benchmark Series – Part 5: Discovery Scripting (Coming Soon)