Guest Blog by Adra Group: Increasing Pump System Performance through CFD

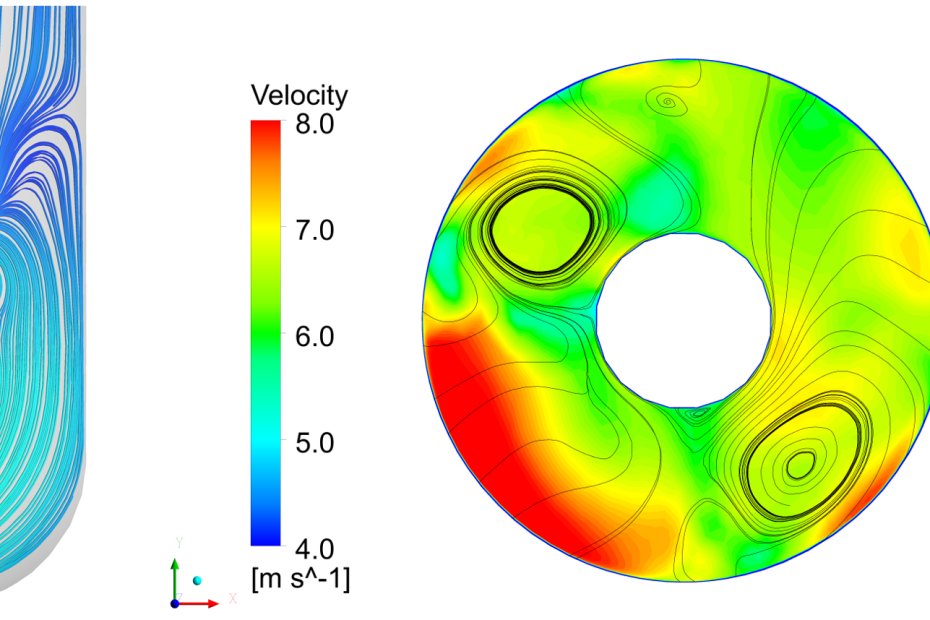

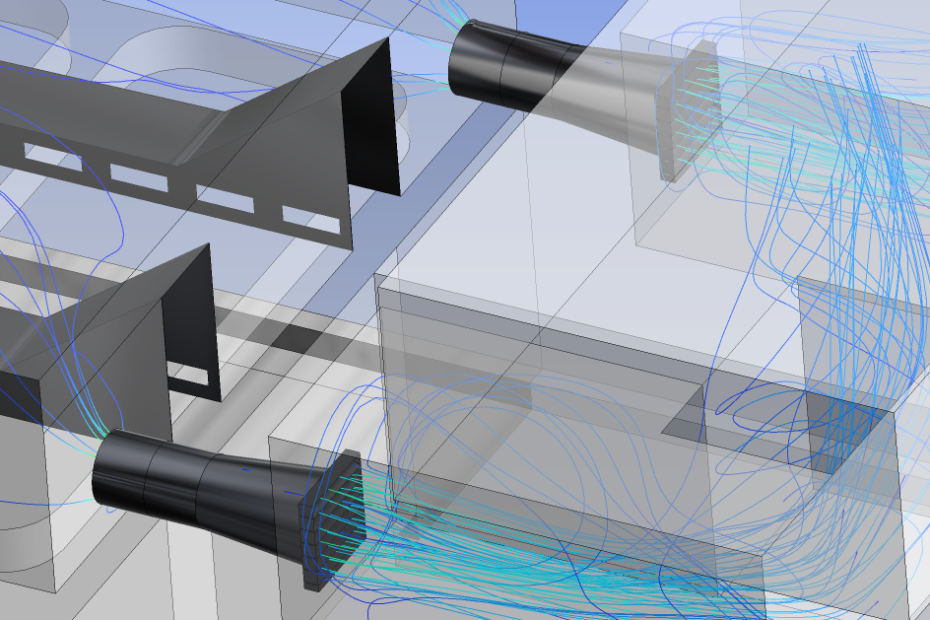

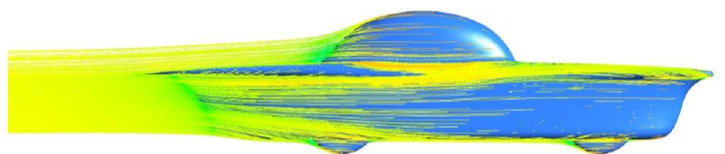

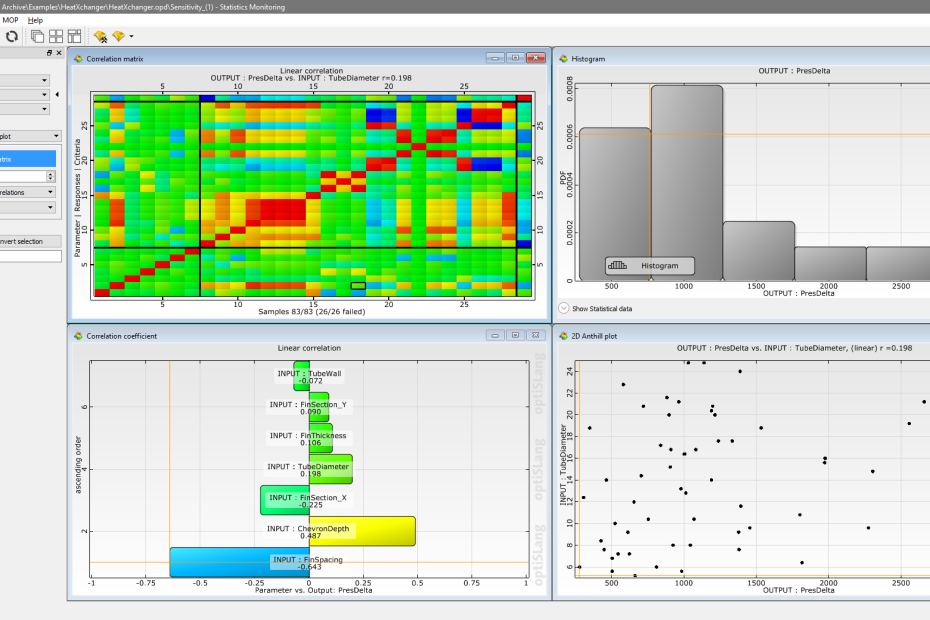

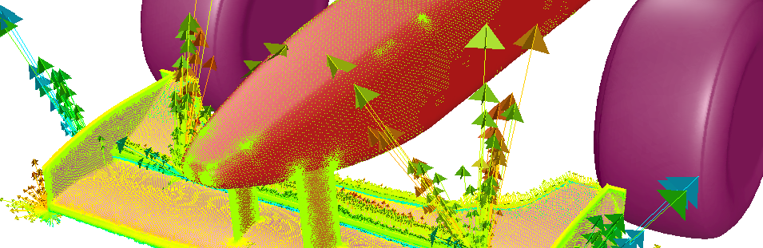

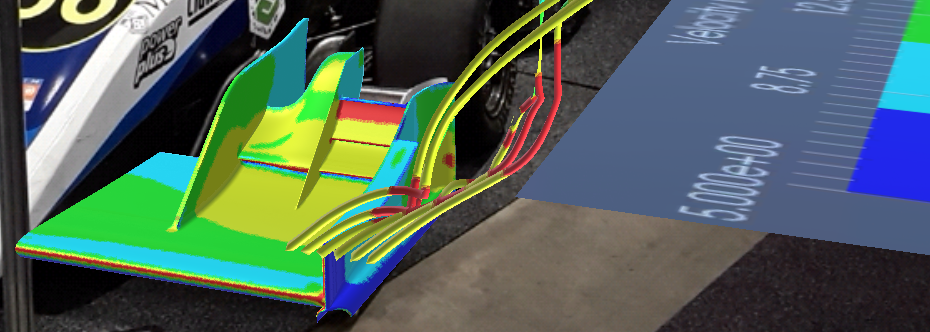

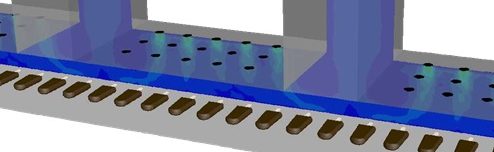

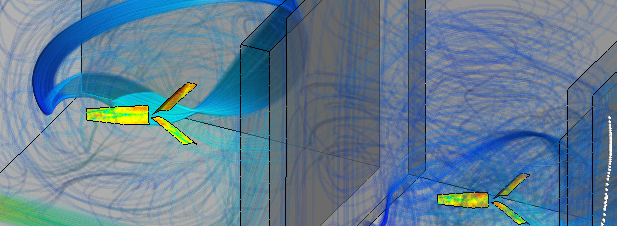

In a guest post, Adra Group explains how ANSYS CFD was used to assist Hydro Australia to identify and resolve non-uniform flow issues (into vertical canister pumps) which was causing severe noise and vibration issues and high operating costs.